Sustainability

Managing Chemical Substances

Chemical substances possess inherent properties that offer outstanding benefits. At the same time, however, chemical substances can harm people’s health and place a burden on the environment if they are misused.

One element of Fuji Electric’s Environmental Vision 2050 is the achievement of a society that is in harmony with nature. To accomplish this element of the vision, we practice appropriate management of chemical substances while working to reduce their use in order to prevent damages to ecosystems.

Managing and Reducing the Use of Chemical Substances

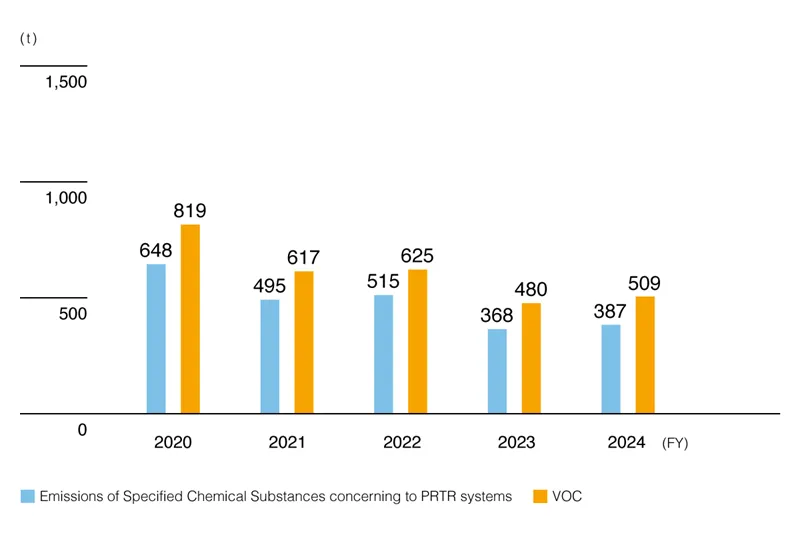

Fuji Electric continues its efforts to reduce its environmental emissions of chemical substances specified by the Pollutant Release and Transfer Register (PRTR)*1 system and atmospheric emissions of volatile organic compounds (VOCs) in accordance with the voluntary action plan put forward by Japan'’s four electrical and electronics industry organizations*2 based on the Air Pollution Control Act.

Starting in 2012, we have also been conducting emissions surveys at our overseas sites, and since then we have been working to reduce emissions throughout the world.

In fiscal 2024, the actual atmospheric emissions of PRTR-designated substances were 387 tons. Additionally, the actual atmospheric emissions of VOCs were 509 tons, achieving the global emission target of less than 800 tons.

-

*1

-

Act on the Assessment of Releases of Specified Chemical Substances in the Environment and the Promotion of Management Improvement

-

*2

-

The four electrical and electronic industry associations were The Japan Electronics and Information Technology Industries Association (JEITA), the Communications and Information Network Association of Japan (CIAJ), the Japan Business Machine and Information System Industries Association (JBMIA), and the Japan Electrical Manufacturers’ Association (JEMA)

Amount of Emissions of PRTR-Designated Substances and VOC Atmospheric Emissions

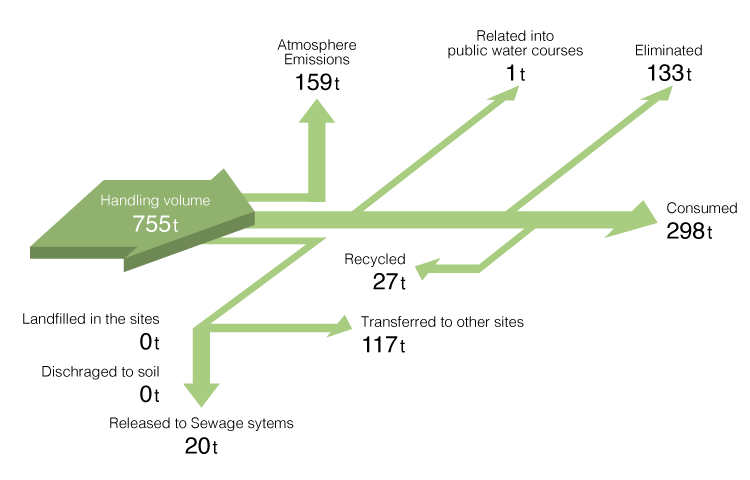

Material Balance of PRTR-Designated Substances in Japan, in FY2024

-

Note

-

Wastewater is properly treated using wastewater treatment equipment at all production bases, and wastewater standards have been met. Accordingly, there have been no discharges of heavy metals or other substances into water environments that exceed standards.

Managing Chemical Substances Contained in Products

At Fuji Electric, we operate in wide-ranging fields—including semiconductors, power generation and electric power, industrial and social infrastructure, and food and beverage distribution—and we provide our products to countries around the world.

Our products contain various chemical substances, and we work to ensure that our customers can use them safely and with peace of mind. We comply with the various laws and regulations governing the use of chemical substances around the world as prescribed in the policy below.

・Fuji Electric Policy on Controlled Substances Contained in Products

“All products comply with all relevant environmental regulations”

To follow this policy, we aim to minimize the risk of chemical substances by systematically eliminating or substituting (to the extent possible and in advance of regulatory deadlines) chemical substances contained in products and used in processes.

Examples of the key laws and regulations—and the countries and regions in which they are effective—to which this policy applies can be found in the table below.

・Management Tools: Green Procurement Guidelines and a Parts Database

To ensure proper management of environmental regulatory substances contained in Fuji Electric's products, we have established the Green Procurement Guidelines. In cooperation with our supply chain partners, we collect information on the chemical substance contents of our products. The Green Procurement Guidelines were revised in December 2024 to reflect new regulatory substances. The obtained information is managed through our internal parts database.

・Regulated substance compliance activity organization

In order to manage and share information on chemical substances contained in Fuji Electric’s products, we established the Environmentally Regulated Substances Working Group in 2003, which consists of design members from each product unit as a company-wide cross-sectional organization that continues its activities to this day. Currently, regular meetings are held twice a year.

・Achievements of Fuji Electric’s attempt to Date

1. In compliance with the RoHS Directive, we have taken the following measures:

- To develop lead-free solder and apply it to products (Completed by 2006)

- To replace lead, cadmium, and mercury in paints, alloys, and electronic materials (Completed by 2006)

- To develop hexavalent chromium-free technologies for steel sheets, plating, and paints (Completed by 2006)

- To replace certain bromine-based flame retardants (Completed by 2006)

- To replace four specific phthalic esters in cables, capacitors, rubber parts, etc. (Completed by the start of the regulations in 2019 and 2021)

A total of 35 X-ray fluorescence analyzers were installed between 2003 and 2004 at all domestic and overseas component factories to perform regular inspections of incoming parts.

2. In compliance with the REACH Regulation, we have taken the following measures:

In order to ensure provision of information on chemical substances contained in products as required by REACH, we have established and revised our Green Procurement Guidelines and built a database of parts and materials, and continue to obtain information from upstream suppliers namely suppliers of parts and materials and provide information to downstream companies namely distributors of our products.

3. In compliance with laws on fluorocarbons namely Montreal Protocol, we have taken the following measures:

To develop and apply CFC-free and GWP 1 refrigerants (R1234yf) for vending machines (Completed by 2011, ahead of the rest of the industry). In fiscal 2011, We developed Vending machines which use of CFC-free refrigerants or refrigerants GWP less than 1 as mass products ahead of the rest of industry

4. In compliance with TSCA PIP (3:1) PBT, we have taken the following measures:

We have completed replacing the materials and components containing the regulated substance in our products by the regulatory deadline of October 31, 2024.

5. In compliance with the EU’s PFAS Restriction Proposal, we have taken the following measures:

When the EU PFAS Restriction Proposal was announced in February 2023, it established a six-month consultation period that ran until September 2023. We submitted comments on all products, parts, and materials affected by the proposal.

With regard to proprietary parts and materials, we made joint submissions with materials manufacturers; with regard to shared parts and materials, we submitted comments through the relevant industrial groups. We will closely watch the future developments as this Restriction is expected to be added to the REACH Regulation.

6. In compliance with the Act on the Regulation of Manufacture and Evaluation of Chemical Substances, with regard to Dechlorane Plus we have taken the following measures:

Decrolan Plus was added to the list of prohibited substances under the Chemicals Control Act on February 18, 2025.

We have completed replacing parts and materials containing Decrolan Plus used in applications subject to regulations. For applications not regulated by law, replacement is also in progress.

7. In compliance with Mineral Oil Ink Regulations (France), we have taken the following measures:

Replacement of inks used in printed materials for France with regulated mineral oil inks has been completed.

・Overseas factory management

We maintain proper management of regulated substances contained in products at our overseas factories through procurement of parts and materials and manufacturing management based on the design specifications of mother factories in Japan.

Supplement

-

CSCL: Japan’s “Chemical Substances Control Low”

-

J-MOSS: JIS “JIS C 0950 Marking for presence of the specific chemical substances for electrical and electronic equipment”

-

Law on fluorocarbons: Japan’s “Act on Rational Use and Appropriate Management of Fluorocarbons”

-

Montreal Protocol: International “Montreal Protocol on substances that deplete the ozone layer”

-

RoHS Directive: EU’s “Directive 2011/65/EU of the European Parliament and Council of June 8, 2011 on the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment” and its amendment (EU) 2015/863.

-

REACH Regulation: EU’s “Regulation on the Registration, Evaluation, Authorization and Restriction of Chemicals (Regulation 1907/2006 of the European Parliament and Council)”

-

TSCA: United State’s “Toxic Substances Control Act”

-

Proposition 65: The State of California’s “Safe Drinking Water and Toxic Enforcement Act”

-

China RoHS: China’s “Act on the Regulation and Management of the Use of Hazardous Substances in Electrical and Electronic Equipment and Products”