Fuji Electric Product Column

The Purpose of Servo Motors

The Purpose of Servo Motors

Technology has come a long way since the invention of the wheel in 3,500 B.C. Technological advancements have allowed humans to live and work more conveniently and more efficiently. With hundreds of thousands of technological breakthroughs throughout history, some of the most important everyday technologies have gotten lost in the shuffle and people have become unaware of their importance over time.

Unbeknownst to most people, parts such as servo motors play a huge role in making people’s lives easier every day. Small technological pieces such as servo motors are heavily used daily in devices you least expect, as you’ll learn with the continuation of this article. It is also used in the industrial field including various of Fuji Electric’s products.

Learn everything you need to know about servo motors - including its purpose, the list of everyday items and machines that operate using it, its advantages and disadvantages, and its parts and their functions.

Purpose

Servo motors or “servos”, as they are known, are electronic devices and rotary or linear actuators that rotate and push parts of a machine with precision. Servos are mainly used on angular or linear position and for specific velocity, and acceleration.

Companies heavily use servo motors because of how compact and potent it is. Despite its size, it generates quite the amount of power and is known to be incredibly energy-efficient.

Most of the companies that use servos are manufacturing companies that need it to position control surfaces and rotate objects at precise angles and distances. Most of the companies that use servo motors are manufacturing companies that use machines with servo motors.

Two Types of Servo Motors

There are two types of servo motors that are available and used in the industrial field.

First is the AC servo motor. This type of servo is currently used today by most companies. AC servo motors are mostly used in industrial fields. AC servo motors are AC motors that rely on encoders. These types of servo motors work through controllers providing feedback and closed-loop control. They are known to function at a high accuracy and are easily controllable.

Second is the DC servo motor. These kind of servo motors were used in the past by Fuji Electric but are rarely used nowadays, as AC servo motors are easier to use, more effective, advanced, and reliable.

Items that Use Servo Motors

Servo motors are utilized by items that are used every day. Home electronic devices like DVD and Blu-ray Disc players use servos to extract and retract disc trays.

Automobiles also use servo motors. In modern cars, servo motors are used to control its speed. When stepping on the gas pedal, it sends electrical signals to the car’s computer. The computer then processes that information and sends a signal to the servo attached to the throttle to adjust the engine speed. Even commercial aircrafts also make use of servos to push and pull everything within the plane.

They are also used for novelty items such as remote-controlled and scale-sized toy cars, toy airplanes, toy helicopters, and toy robots. Servos are especially helpful for radio-controlled airplanes to position control surfaces.

But servos are mostly used for industrial purposes. Important industries such as robotics, pharmaceutics, food services and in-line manufacturing also make use of servos.

Servos are also most-suited for electrically operated pieces of machinery such as elevators, rudders, walking robots, and operating grippers.

Advantages and Disadvantages

Servo motors provide quite a lot of advantages but as with all things, they also pose some problems and difficulties for companies who utilize this device.

Advantages

Servos are known to always be frequent and work at the same pace. So, if a heavy load is placed on the motor, the driver will increase the current to the motor coil as it rotates the motor. This basically means that servo motors are expected to always be mechanically on point. And because of its precision, it allows companies to operate it at a high-speed pace.

Disadvantages

As with anything that provides convenience and efficiency, servo motors also tend to have a high cost when it comes to maintenance and operation. Moreover, when a machine using a servo is stopped, the motor continues to move back and forth one pulse, so it is not good if the machine or area is not suitable with vibrations.

Servo Motors Parts and Functions

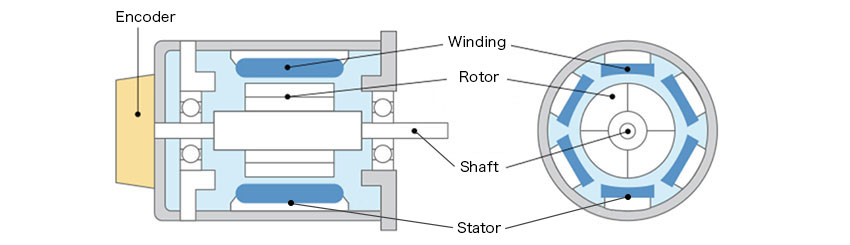

Dozens of parts make up a servo motor with each and every single part playing a vital role in the device’s functionality. Here are its most important parts and the significant roles they play in the functionality of the servos.

-

Stator - A stator creates a rotating magnetic field to efficiently generate torque.

-

Winding - Current flows in the winding produces a rotating magnetic field.

-

Shaft - The shaft transmits the motor output power. This load is driven through the transfer mechanism.

-

Rotor - A rotor is a permanent magnet that is positioned externally to the shaft.

-

Encoder - An optical encoder always observes and calculates the number of rotations being completed and watches the position of the shaft.

Each part of the servo motor serves a huge purpose in making the servos properly function or work.

Conclusion

Servo motors are one of the most vital devices on the planet today, even though most of the world’s population is unaware of its existence and importance. Many companies continue to rely on servos because of their reliability, precision, efficiency, size, and potency. It won’t be much of a surprise if businesses will continue to use these helpful devices in the many years to come.