The labor shortage issue is incurred due to the decline of the working-age population.

The key to solve the issue is "Sho-kō-sū", a labor-saving solution.

The "Spring Terminal Equipment" achieves the "Sho-kō-sū".

The decline of the working-age population will impact the number of workers in the manufacturing field.

The "Spring Terminal Equipment" provides the solution.

Switch Control Development Department,

Development DivisionKoji Asakawa

Interviewed in March 2018. Title and affiliation recorded were at the time of the interview.

The reasons for the popularity of "Sho-kō-sū" in the manufacturing and maintenance sites.

- What are the reasons for the popularity of "Sho-kō-sū" in the manufacturing and maintenance sites?

- Asakawa

- The labor force in Japan has been decreasing since 1992, the peak year. Aside, the number of people engaged in the manufacturing industry is decreasing; the number of workers on site is also decreasing. There are other reasons as well: the surge of electrical equipment demand toward the Tokyo Olympic Games and the work-style-reform promotion to reduce working hours.

Therefore, we forecast that the demand for the "Sho-kō-sū" - reduction of labor resources per work including actual hours and manual labor - in the manufacturing and maintenance sites will be higher.

A keyword for the sho-kō-sū is "screwless". It is a simpler method than the main method of using the screws. Screws has widely been used for electrical installations; yet the method of "remove screws, use a thread crimp terminal and tighten the screws again" takes significant time and resources. Therefore, we developed "Spring Terminal Equipment" and "Plug-in Equipment" using the method of connecting wires without screws.

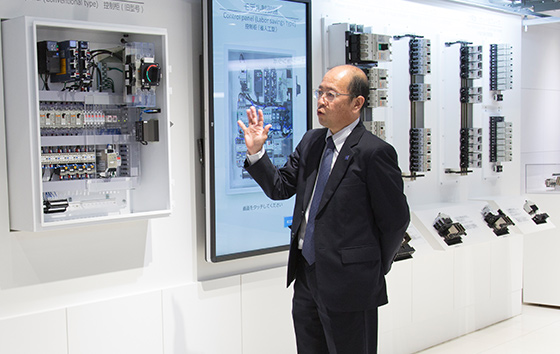

What is "Control Panel" that uses the "Spring Terminal Equipment"?

What is "Control Panel" that uses the "Spring Terminal Equipment"?

- We heard that the "Spring Terminal Equipment" is mainly used as a "control panel" for machine and equipment. What are the features of control panel?

- Asakawa

- The control panel controls the electricity flow for big machinery and equipment in factories. The control panel may contain power supply of the control circuit system, timer, inverter, servo system, programmable logic controller (PLC) and so on. You can think of it as a collection of equipment for shedding and controlling electricity in one place.

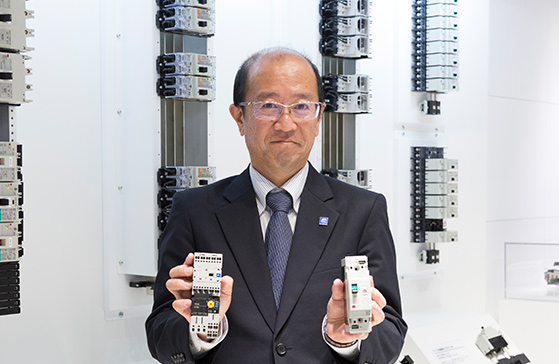

What is "Spring Terminal Equipment"?

- What specific product group does the "Spring Terminal Equipment" belong to?

- Asakawa

- In the past, the major method of connecting various devices and wires in control panel was screw-type terminals. Spring terminal equipments are used to convert this into spring terminals. Spring terminals are used to fix the wire by pinching the wire spring. When inserting electric wire to a spring, the wire gets inserted to a leaf spring made of stainless steel and is fixed. There is no need to open or tighten screws as in the past, and the work can be completed by just inserting the wire. Therefore the time required for the operation has greatly been decreased. Compared to the conventional screw type, the time required for the operation is reduced by 30% to 60%.

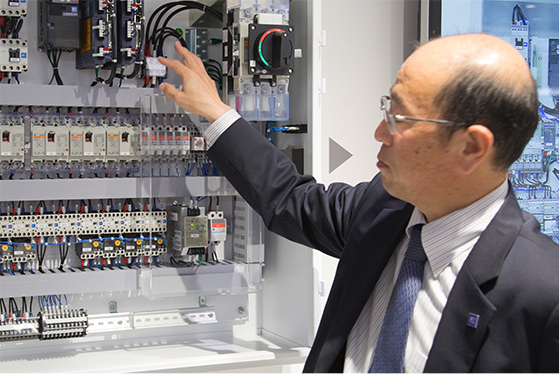

- The equipment for the main circuit in the "Control Panel" seems to have been missing the "Spring Terminal Equipment" until now. What's the reason?

- Asakawa

- Equipments such as control circuit system, power supply, timer, inverter, servo system, programmable logic controller (PLC), etc. in the control board are currently a part of the spring terminal conversion. But until now, equipments for the main circuit were not included in the conversion.

The main reason was the high current and voltage in the main circuits, which required a high reliability to the connection part with electric wires. Therefore, comparing to other equipments for control circuit systems, the technical challenge was higher. To provide sufficient reliability, we researched the raw materials and plating used for the terminal part and the structure of electric wire holding.

- Please tell us the market impact of the "Spring Terminal Equipment".

- Asakawa

- Other domestic manufactures offer similar spring terminal devices. Utilizing spring terminal devices, customers can achieve 80% of the inboard equipment connecting with spring terminals devices and benefit greatly from "Sho-kō-sū".

What are the benefits of the "Spring Terminal Equipment"?

- What are the benefits of installing the "Spring Terminal Equipment"?

- Asakawa

- First the wiring time is short because it does not use screws. Next, skilled workers for wiring are no longer needed because the work is simple. In addition, work hour can be reduced as you can avoid troubles such as screws falling down while you are working.

Screws may become loose due to vibrations; therefore by not using screws it enables to reduce the number of steps, such as periodic inspection and retightening.

One of the problems using screw was that the screws may become loose due to vibrations; therefore not using screws can reduce the time spent for inspection and retightening.

In addition, it is safer than screw-fastened parts as the part electricity flow is insulated.

- Are the "Spring Terminal Equipment" compatible products technically difficult? Please also tell us the advantages over other manufacturers.

- Asakawa

- We originally had the technology on electricity flow to contacts such as switches. We believe that the relevant technology has been attributed to the development of these products.

Basically, the structure of our "Spring Terminal Equipment" is very simple. However, at the same time it is difficult because it is simple.

Furthermore, we are committed to make our products easy to use. Right now, we are adopting the push-in method that connections get completed when electric wire is just pushed into equipments for main circuit and control circuit systems. Other manufacturers usually open the spring using tools and inserting the line into the spring. This is one of our competitive advantages over others.

What is the future of "Spring Terminal Equipment"?

What is the future of "Spring Terminal Equipment"?

- Please tell us your thoughts on the "Spring Terminal Equipment".

- Asakawa

- Securing human resources and passing the tradition of technology are becoming a challenge for not only the manufacturing industry but also for various industries. We believe that our "Spring Terminal Equipment" can contribute to the measurement on the decreasing labor force population.

We aim to contribute to the global society by advancing "Sho-kō-sū" from the aspect of equipment.

- What kind of deployment are you planning to develop "Sho-kō-sū" products such as "Spring Terminal Equipment"?

- Asakawa

- Spring terminal equipment has been released in June, 2018; our development started since then. I would like to reflect customer feedbacks to the future product development. For example, there may be development to further expansion of the product lineup. Again, I would like to develop products that can meet customer needs.

~ Spring Terminal Equipment ~

Reduction of Wire Work and Improvement of Quality and Safety.

"Sho-kō-sū" Components of Fuji Electric FA Components & Systems.

This product is recommended for:

- Customers considering to improve the efficiency of control panel production

- Customers facing the issues on the technology succession and human resources development due to the decrease of labor population

- Customers wanting to further miniaturize control panel and improve safety

Background and Challenges

- With the situation of labor force decrease and working hour decrease due to work style reform, the efficiency improvement in manufacturing and maintenance site is being required.

- The facilities where require all-time electricity have increased; construction time (power outage time) is required to be minimized.

Achievements and Improvements

- By adopting the equipments that use screwless spring terminals to the control board, the entire control board has realized the screw-less ness. This adoption further secures "Sho-kō-sū" and the stable quality.

- Plug-in equipment realizes more efficient wiring work inside the power distribution and distribution board ("Sho-kō-sū" realized). It also contributes to safety improvement and miniaturization.

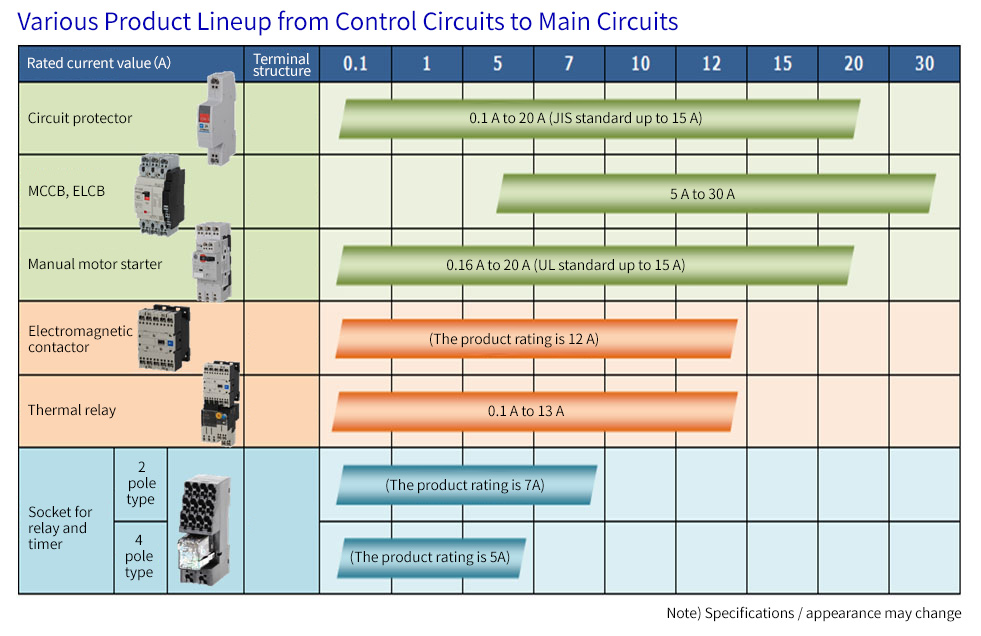

~ What We Offer ~

Sho-kō-sū Equipment by Fuji Electric FA Components & Systems

Spring Terminal Equipment

- Deutilization of screws contribute to the improvement of work efficiency as work hours for wiring can be reduced. (about 30% reduction)

- It is skill-less as no torque management and no retightening of screws are required. Maintenance work can be reduced. In addition, contact quality can be improved.

- The detail-oriented design helps realize "Sho-kō-sū" and bring various merits such as smooth wiring display, safety of work and space saving.

Fuji Electric FA Components & Systems is different:

- The world's first push-in method for circuit breakers, earth leakage circuit breakers and electromagnetic switches

- Electricity and design technology accumulation for many years in contact equipment realizes

high reliability and miniaturization of terminal connection part