Breakers and Contactors are converted as IoT sensors

Flexible and Low-cost IoT Solutions Created by Reverse Thinking

Internet of Things, in short, IoT, is currently a hot trend.

When connected to the Internet, many different things can be possible. So what specifically can we bring to the manufacturing industry?

In particular, what issues can be solved for the small and medium-sized manufacturing industry?

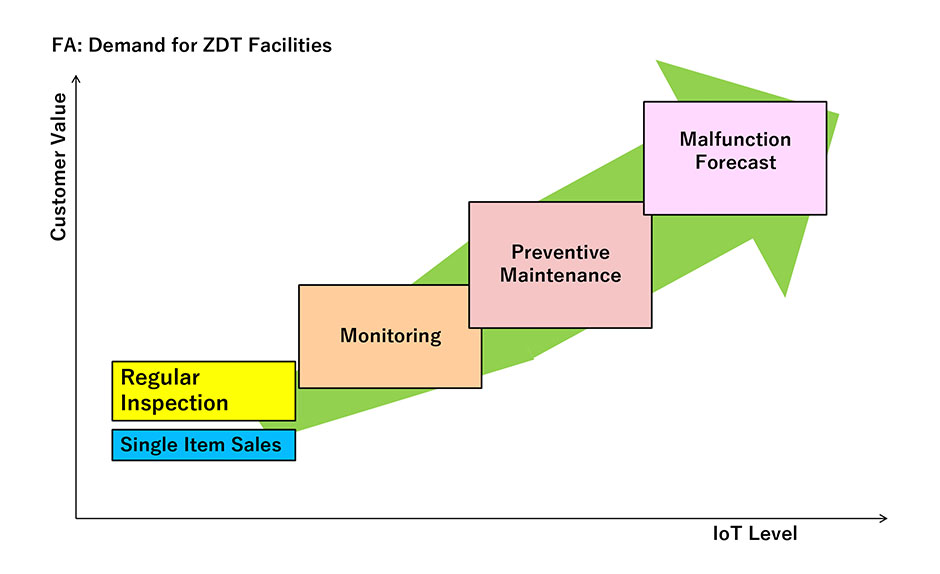

There is a shift in demand. In the past, only periodic inspection was required, whereas the demand is extended to condition monitoring and preventive maintenance that can forecast malfunction by utilizing life-cycle diagnosis and highly advanced technology.

IoT is a hot topic. How can IoT change the world?

- In the manufacturing industry, "IoT (Internet of Things) is a high-trendy topic.

- Hayama

- Various organizations including the IIC in the United States, the Industry 4.0 in Germany and the Robot Revolution Initiative Council in Japan are discussing its potentials; and there are activities to establish international standardization. As the world is moving toward the realization of IoT, securing competitiveness is urgent for all the enterprises regardless of its size.

- Tazawa

- In the same context, some of your bosses just told you that "You are now in charge of IoT" and many of you have searched for everything related to IoT. For the Japanese manufacturing industry where various Kaizen's and automation have been already successful, it might be difficult to imagine the advantages of IoT.

- When introducing IoT to the manufacturing industry, what can we expect?

- Hayama

- The big goal for the manufacturing industry is the "Equipment Zero Downtime (ZDT)". It is to reduce the factory downtown to zero, which have been caused by equipment and facility malfunction. Depending on the type of industry, the cost of loss caused by one day's downtime is said to be hundreds of millions of yen, so many of our customers want to keep the downtown as short as possible.

- Tazawa

- Therefore it is our niche market. In general, IoT in the manufacturing industry is the on-site installation of various sensors to collect, analyze various data and connect it to Kaizen. Our component products have already been installed on-site as control and protection equipments that are indispensable for electric systems also function as electrical energy and operation monitoring sensors for electrical equipment and various equipment.

Using a component as a sensor, IoT can start small.

- When mentioning a sensor, I imagine something like detecting vibration, speed and temperature.

- Hayama

- Basically components such as a breaker and an electromagnetic switch are sensors that detects and controls electricity flow. However, these sensors are not directly connected to the network; so we need to connect it to the network.

- Tazawa

- Prior to the era of IoT, we had power energy monitoring products utilizing the sensor function in our product line-up that we called F-MPC series. Our proposal is to utilize these products as a starting point to IoT. Installation can be carried out easily by combining the I / O of a breaker or an electromagnetic switch that are already installed in the customer's distribution panel or control panel.

- Hayama

- Also, the F-MPC series incorporate power monitoring and energy-saving control mechanism in one suite that does not require a programmable controller (PLC) or a dedicated program; once you install the F-MPC, you can start using it immediately from any browser on any computer. It is an example of a prompt but small start of IoT proposal from the Fuji Electric Group.

- I feel that there is not much you can say about IoT when you are only monitoring the energy.

- Tazawa

- Indeed. Our current proposal is to develop advanced mechanism for IoT and expand its usage not only to conventional energy monitoring, but also to preventive maintenance by equipment and operational management of equipments; equipment condition monitoring and lifetime diagnosis.

- Hayama

- Electricity monitoring is the basic mechanism for measuring the energy, checking usage, issuing alerts when a certain value is exceeded, and controlling the equipment. Same technical reasons can be applied to operational management. Our customers can have another benefit that is preventive maintenance from electricity monitoring, because it can help customers manage various operations such as machinery equipments, operating cycles, hours, and current of manufacturing equipments.

- Tazawa

- For many customers, equipment diagnosys is done by performing periodic inspection at a fixed cycle and post-maintenance at the time when the faulty equipment should be replaced. If we can collect data for entire manufacturing line including equipment operation condition, operating cycle and hours, we can proactively perform preventive maintenance prior to its actual break-down.

First from the operation management of facilities. To the central identity of manufacturing of the future.

- You can retrieve a lot of data just by measuring the flow of electricity.

- Tazawa

- It may resemble "blood pressure" in our human body. We can forecast the health status of the machines looking at the actual operation times and the running-hours as the specification of the machine provides statistical forecast of its lifecycle.

When some activities are stronger than normal, we can assume that the possibility of having an issue is high. In that sense, you can find symptoms of malfunctions/failures via electricity data flowing through equipment before running a thorough diagnosis of the inside of the manufacturing equipment. - Hayama

- In terms of collecting data, we have our famous and long-history of technology for breaker and electromagnet switches; so our sensing technology can take accurate data from over-current electricity. However, we have just started product development for IoT; we do not have the capacity to gather all data that customers require at this moment.

We want you to benefit from the potentials of IoT as soon as possible.

- What are the potentials of IoT?

- Hayama

- As for the potentials of IoT in manufacturing, there is an index called "QCDS" in manufacturing. Q is Quality. C is Cost, D is Delivery and S is Safety / Security. IoT can contribute to all of these. For example, from Q, the quality. From the vast amount of data on the manufacturing process, we can acquire data related to product defects and analyze and make the cause of the visible problem. In the future, AI will be implemented to measure autonomously.

- Tazawa

- We are still finding out what each company is doing, what we can do with IoT, and where the customer's demand is. Some of you may be worried that if you start IoT with our products and services, IoT will lock the rest of operation and prevent to use products from other companies. However, IoT is assumably an open system; we are actively participating in consortium activities such as i-BELT which is an open platform for IoT and trying to eliminate concerns little by little.

- Hayama

- Furthermore, there are several movements to establish a new international standardization as to the premise of the spread of IoT and the forthcoming of the Fourth Industrial Revolution which is supported by the rapid technological development regarding electronic devices and information communication.

The international standards will be established in a few years. Compared to the example of VHS and Beta, of which the flexibility was not provided by the manufacturers and the standards, and the investment worthed nothing in the end; the investment risk of IoT is said to be low. - Tazawa

- IoT is a tool to find a key to solving problems in your daily work. It can collect data that were previously not available as facts, also it can gather a huge amount of data that previously it was not possible to process even after the acquisition of data. A new door is open, thanks to the various technological innovations, and the development of the communication infrastructure. I would like you to open the door as quickly as possible and get ready to take out the mountain of treasure.

~ F-MPC Web unit ~

Connect data by the control panel component for a small & quick IoT start.

Support energy saving plans and preventive maintenance

Our Recommendations for:

- Clients considering to start IoT.

- Clients of medium to small scale factories (with the number of monitoring spots: about 1,000 spots scale)

- Clients aiming for zero downtime in production facilities.

- Clients considering IoT as of a part in large-scale factory and the possibility of expanding from small to medium scale system.

Background and Challenges

- You have the intention to utilize IoT, but in reality don't know what to do or where to start. You currently can not make a heavy investment as you do not know the exact cost-effectiveness at this time.

- Operation of production facility is not being monitored, and with limited resources on periodic inspection and daily report information, you can only manage the post-issue maintenance.

Achievements and Improvements

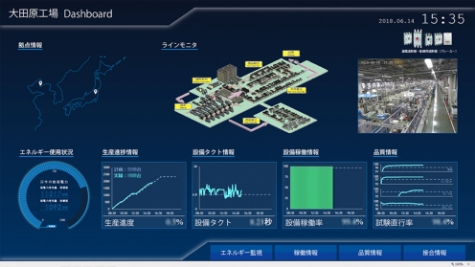

- As the first step of IoT, it helped to monitor the operation status of machinery facilities. Also the initial cost was relatively low.

- It became possible to monitor the operation status and manage alerts with a general-purpose personal computer. It was easy to change the alert setting and responded quickly to any change of the status.

- By monitoring the operation status of production facilities, it became possible to take specific data on operation.

~ What We Offer ~

Introduced Solution:

Energy-data-collect controller F-MPC Web Unit

- Easy operation of data collection, "Visualization", form creation for energy saving policy.

- Energy saving support including air-conditioning control by providing demand monitoring and pattern control.

- Preventive maintenance support by monitoring the operation status of equipment and facility and by alert

functionality.

Fuji Electric FA Components & Systems is different:

- Installation, control, monitoring, preventive maintenance from any browser on any general purpose PC.

- Without requiring dedicated programs and PLC, IoT can be started with low cost.

- It can start partially in the beginning. Later-stage expansion is also possible.