MICREX-VieW FOCUS Evolution

Prolonged stable and dependable plant operation

with easy customization and high redundancy

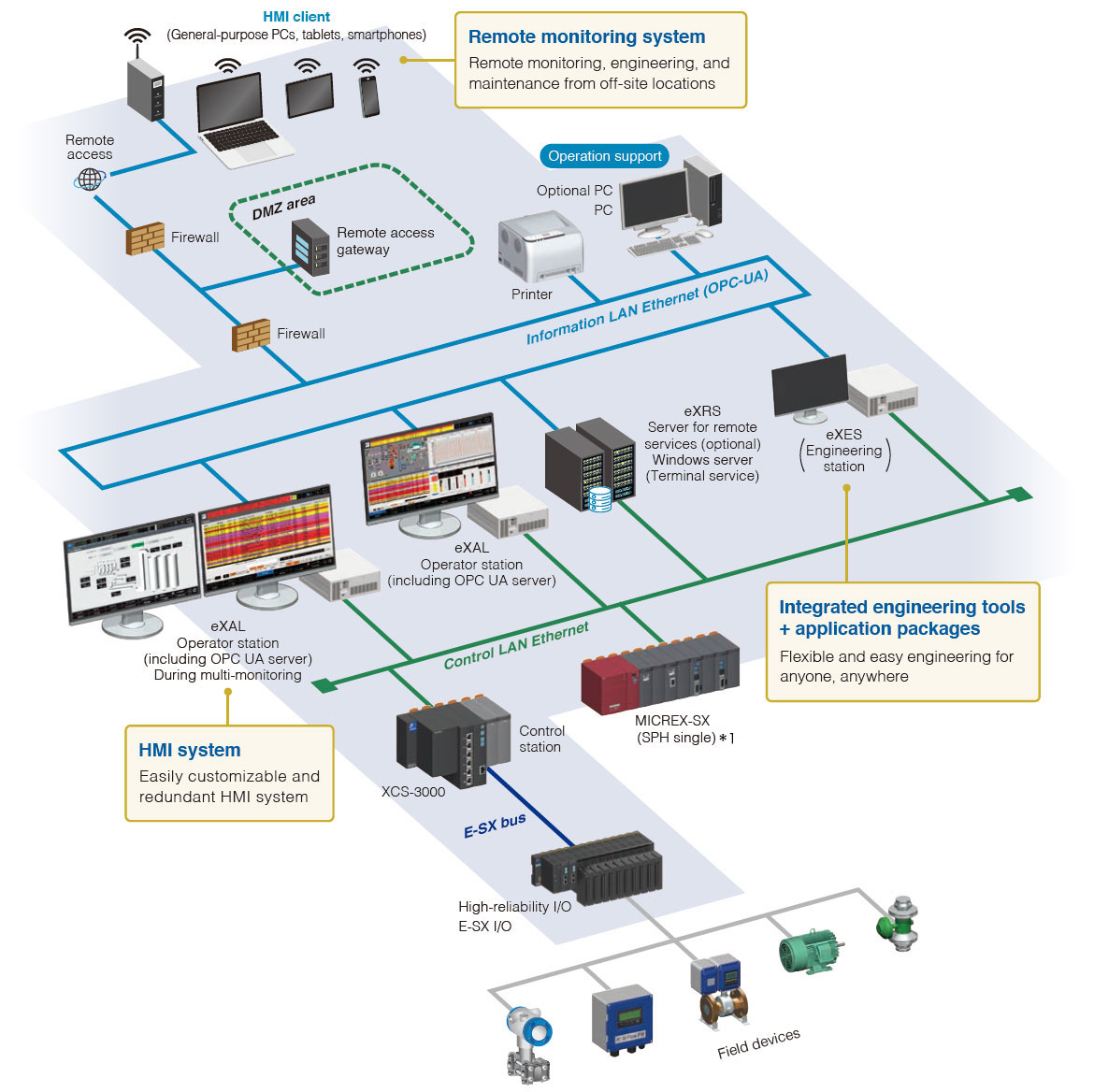

MICREX-VieW FOCUS Evolution can be flexibly configured according to the scale and purpose of use, and can be operated globally.

It also supports stable plant operations through remote control using smart devices.

It combines easy customizability and high redundancy, making it a constantly evolving monitoring and control system.

*1:This will be supported in future

HMI system

Easily customizable and redundant HMI system

Reduces costs by adopting a proprietary database

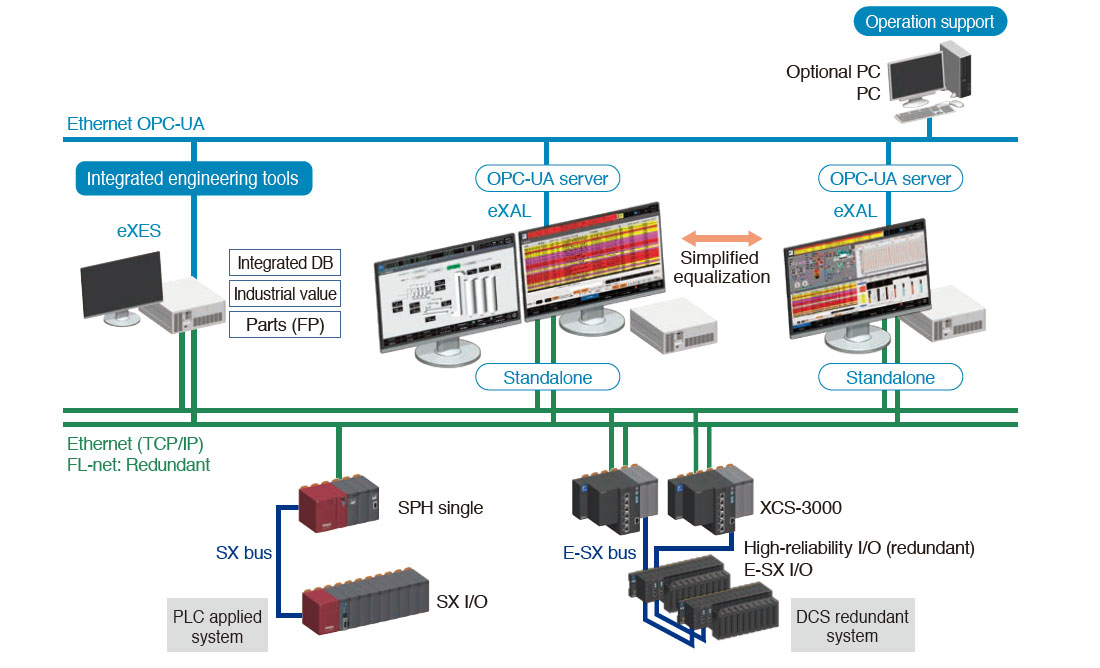

Proprietary database eliminates the need for an SQL server. Extends the range of equipment selection and helps reduce installation costs (Expands a selection: From FA-PCs to general-purpose PCs, FL-net to TCP/IP redundancy*1).

Supports redundancy to achieve highly stable operations

Implements redundancy by maintaining databases on multiple HMIs. In the event of a failure, it supports immediate data recovery and continuous operations.

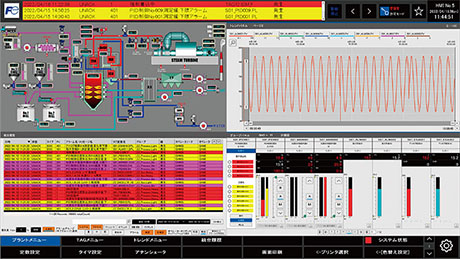

Improves productivity using multiple windows

Displays multiple related windows on a single display. Necessary information can be easily understood and checked at a glance.

Enhanced stability through system integration

Promotes plant stabilization by linking with Fuji Electric’s operation support package*1. Contributes to safe operations.

List of operation support packages

- Plant operation assistance

- Abnormal sign detection

- Plant panel playback

- Fail-safe procedures

- Remote support

- Instrument data collection

- Model forecasting

- S88

- Part11

- Alarm management

Equipment monitoring grouping

Grouping multiple plant facilities and linking them to HMIs prevents facility panel displays and alarms other than those of the specified group. This prevents operators from inadvertently operating non-applicable facilities or mistakenly identifying alarms.

*1:This will be supported in future

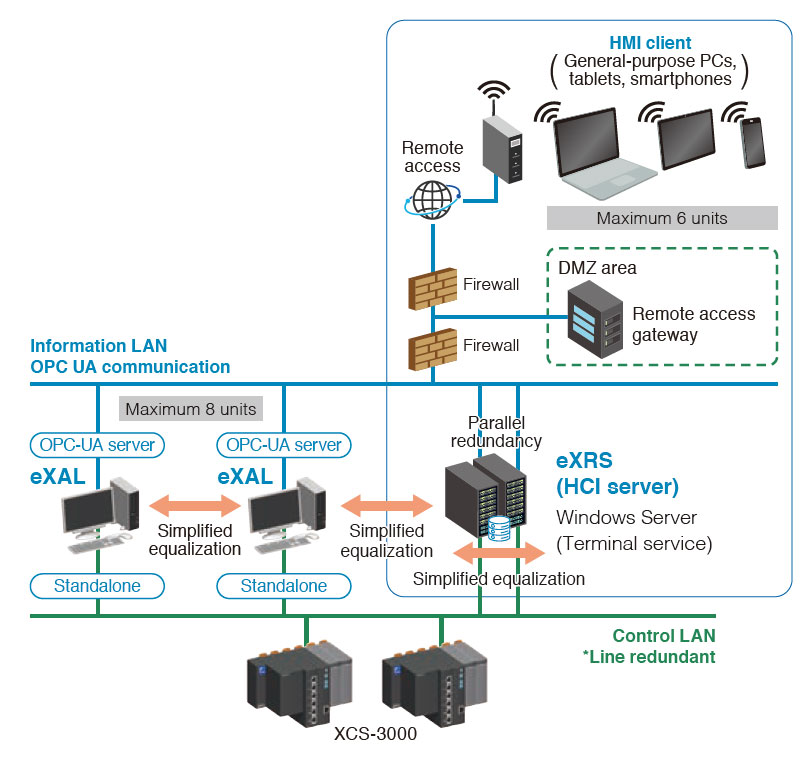

Remote monitoring system

Remote monitoring, engineering, and maintenance from off-site locations

Remote monitoring and control from anywhere

Multiple HMI clients*1, including general-purpose PCs, tablets, and smartphones, enable users to perform remote monitoring and control from off-site locations.

Client connections form networks

Connects up to 8 HMIs (eXAL) and 6 HMI clients via HCI servers (eXRS). Up to 14 units can be used simultaneously.

Adopts OPC UA communication protocol

Uses the OPC UA communication protocol, an international standard open interface. Smoothly implements data linkage with upper-level systems.

*1:This will be supported in future

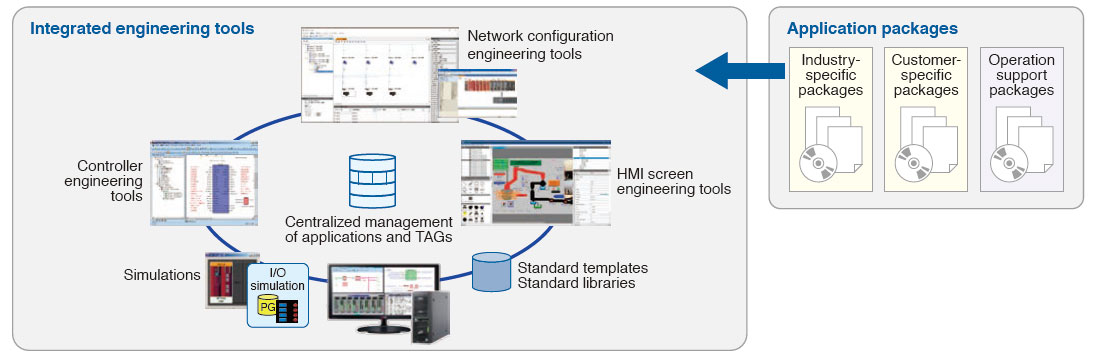

Integrated engineering tools + application packages

Flexible and easy engineering for anyone, anywhere

Flexible system construction

It allows users to create integrated engineering environments suitable to the size and industry of their plants.

Highly flexible system design

System configurations and application packages can be created according to user requirements.

Drag and drop

Each component such as HMIs, controllers, and networks can be engineered using drag and drop from the catalog of tools. Supports easy and fast deployment.

Reduces design-related costs

Multi-user engineering, simulation, and TAG sharing reduce engineering costs and labor hours.