Going beyond perfection

For over three decades, the "New SC Series" magnetic starteres by Fuji Electric FA Components & Systems have been the benchmark in the manufacturing world.

Our pursuit of perfection has been the driving force behind our continued success.

With our latest product, the SC-NEXT, we are breaking boundaries and pioneering a new era of innovation. It's a testament to our commitment to surpass ourselves and provide revolutionary performance that's essential for a better future.

About SC-NEXT

By investing in advanced equipment and processes,

companies can achieve higher levels of

efficiency within a smaller operational footprint.

Building better control panels for a brighter future.

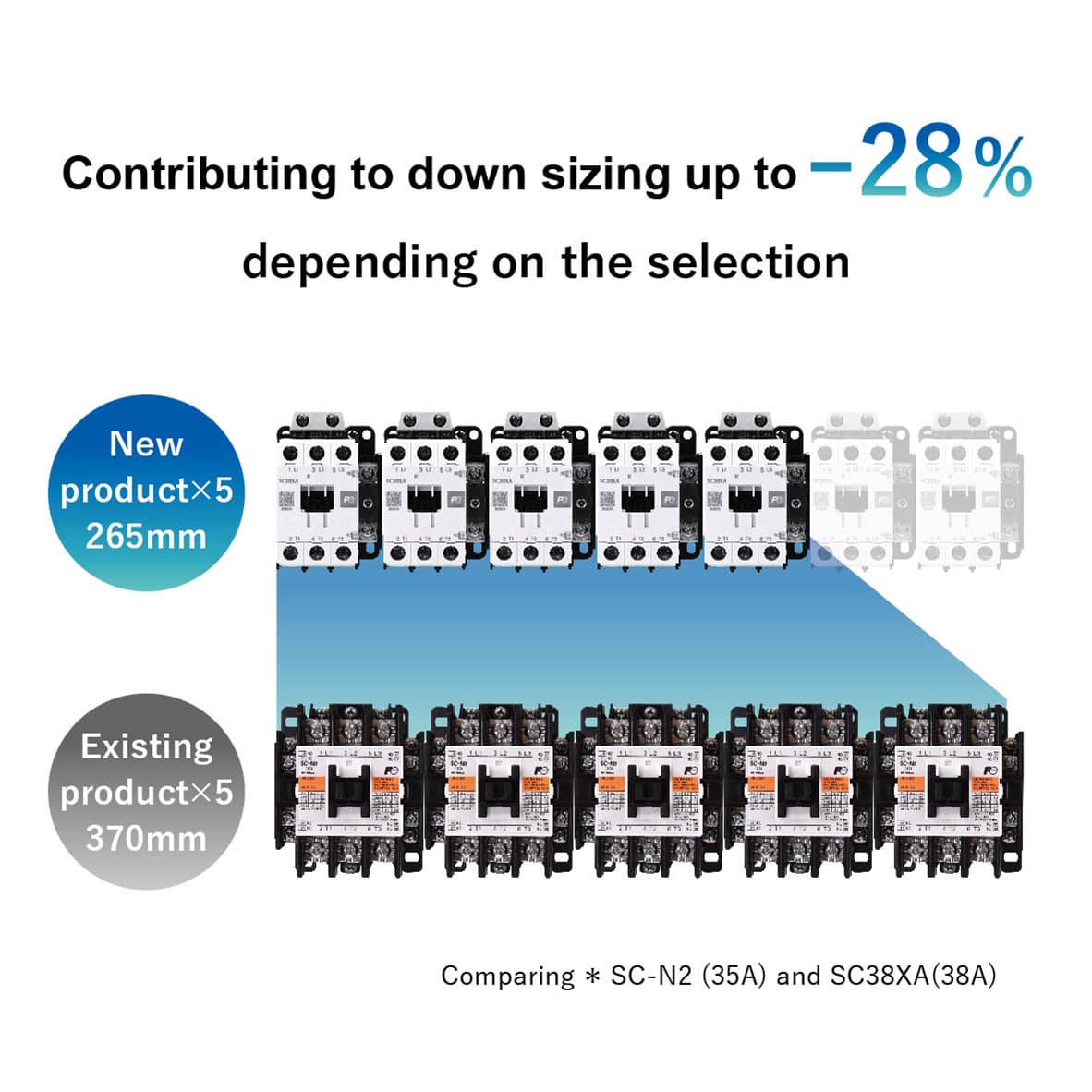

Designing control panels can be a daunting task, especially when it comes to adding equipment without changing the panel size. But with our innovative SC-NEXT, we have overcome this challenge by creating a solution that is up to 28% smaller depending on the model selected. Our dedication to creating space-saving and high-performance control panels has led us to develop this ground breaking technology.

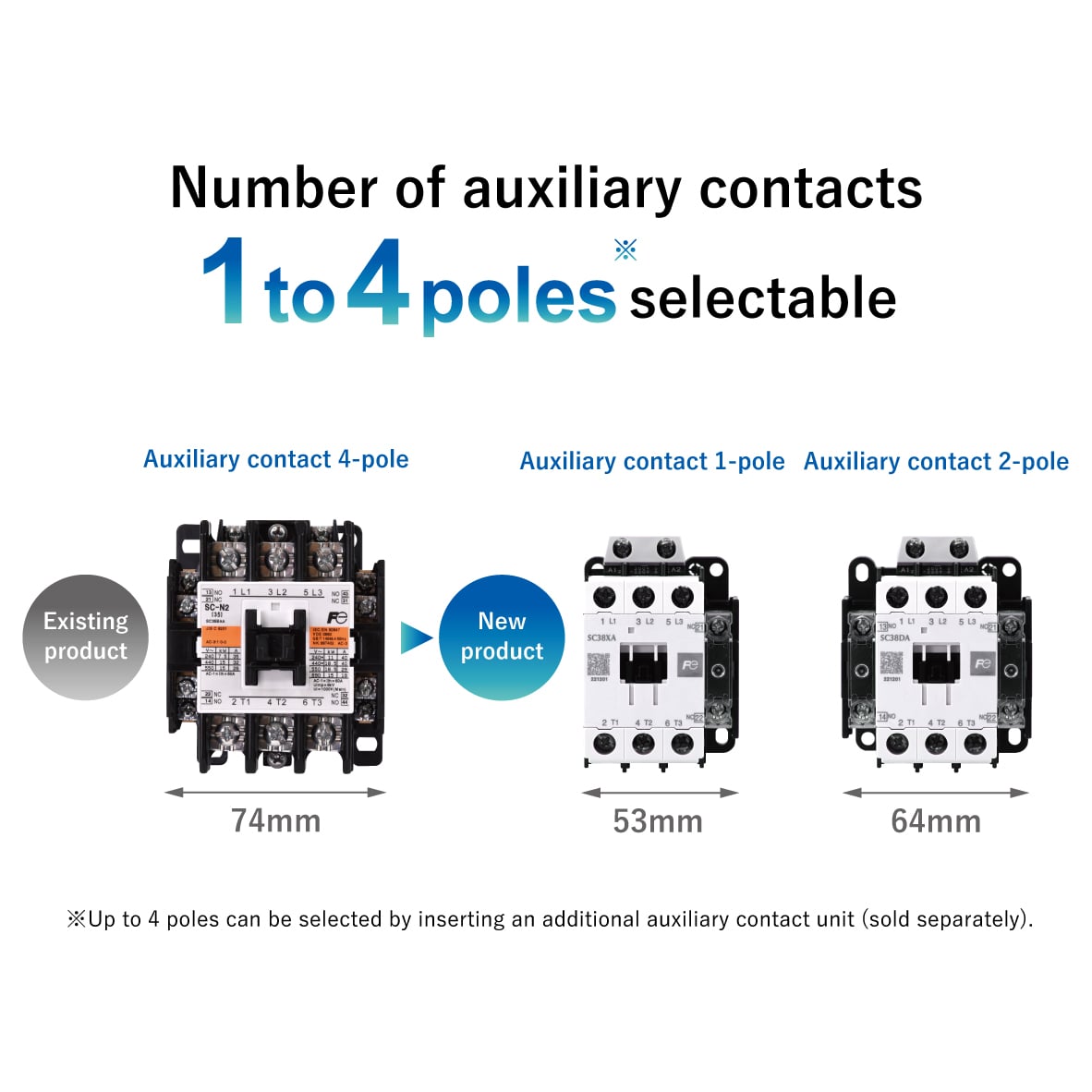

The auxiliary contact configuration can be customized to fit your specific requirements.

In fact, we have discovered that about half of our magnetic starter users use only one pole. For this reason, we offer a variety of auxiliary contacts to suit customer applications. To ensure compatibility, it is of course possible to select the same number of contacts as in conventional products, but further downsizing can be achieved by reducing the number of contacts as required.

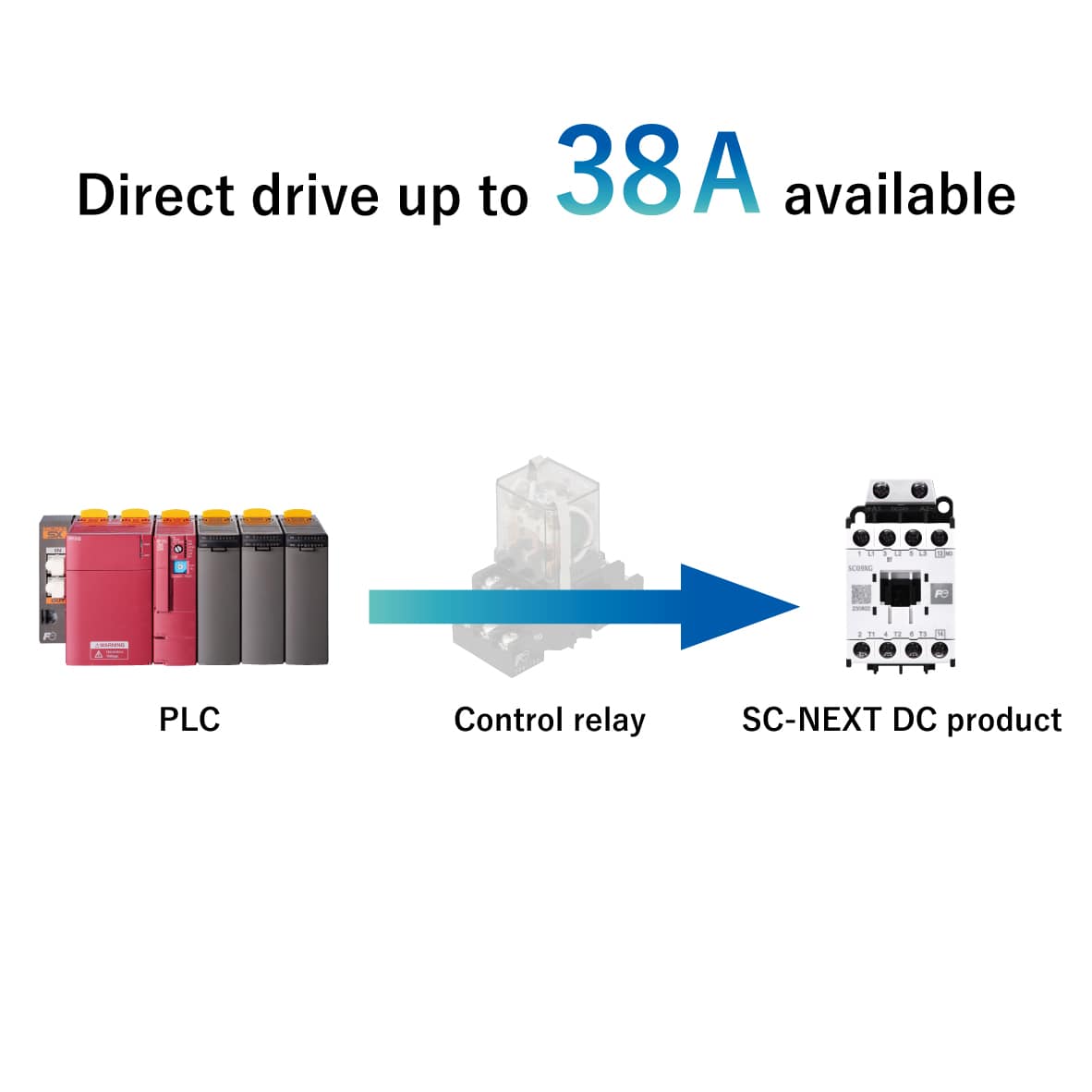

Enables PLC direct driving.

Contributes to further downsizing.

SC-NEXT is the first Japanese product to enable direct driving from a PLC up to 38 A. This eliminates the need for relays and IC coil drive unit, and reduces the space required for the control panel.

Low-power consumption types are only available for direct driving for DC products.

Make on-site operations safer and more intelligent.

A standard device that protects the safety of everyone who handles products.

It includes a terminal cover as standard to ensure IP20 finger protection. Increases safety during maintenance and inspection.

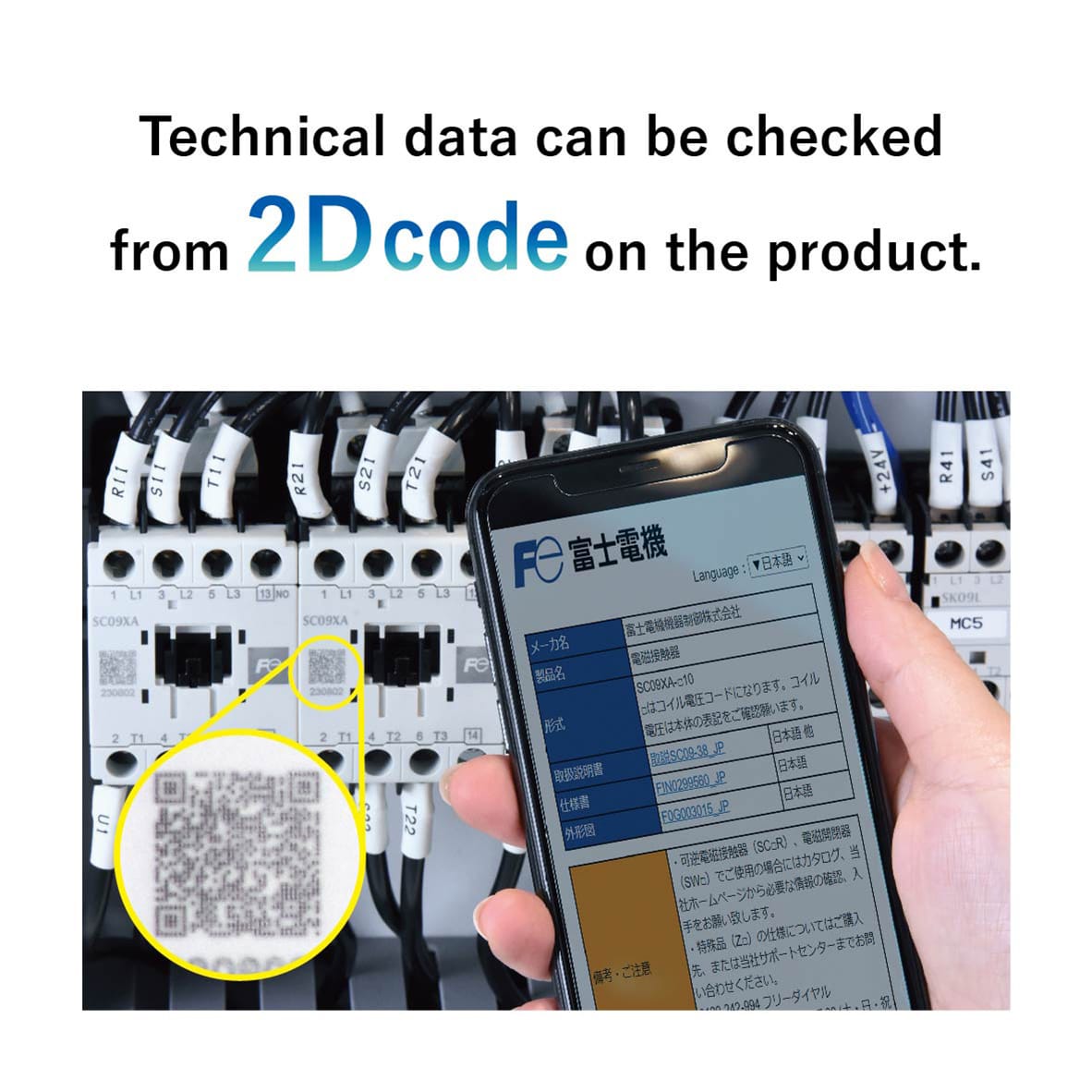

Get the specification you want to inspect right away.

A 2D code is attached to the surface of the product that allows users to check documentation on product specifications, outline drawings, and user manuals.

If you need clarification, simply scan the 2D code to get the answers you need right away.

Increase your contributions to environmental initiatives.

Products that have been used are recycled.

Product development with the goal of recycling in mind.

98% of the plastic used in SC-NEXT is made from recyclable resources. This helps to make carbon neutrality a reality.

![[AC operated] power consumption Max. 25% reduction [DC operation] power consumption Maximum 73% reduction](/fcs/sc_next/assets/img/top/ph_about_03-02.jpg)

Significant energy savings are achieved.

Contributes to reducing energy consumption.

For both AC and DC-operated types, SC-NEXT dramatically lowers coil power consumption. Reducing energy consumption is made possible by the fact that the DC-operated type is up to 73% smaller than the conventional product and the AC-operated type is up to 25% smaller.

To extend the life of our products for customers.

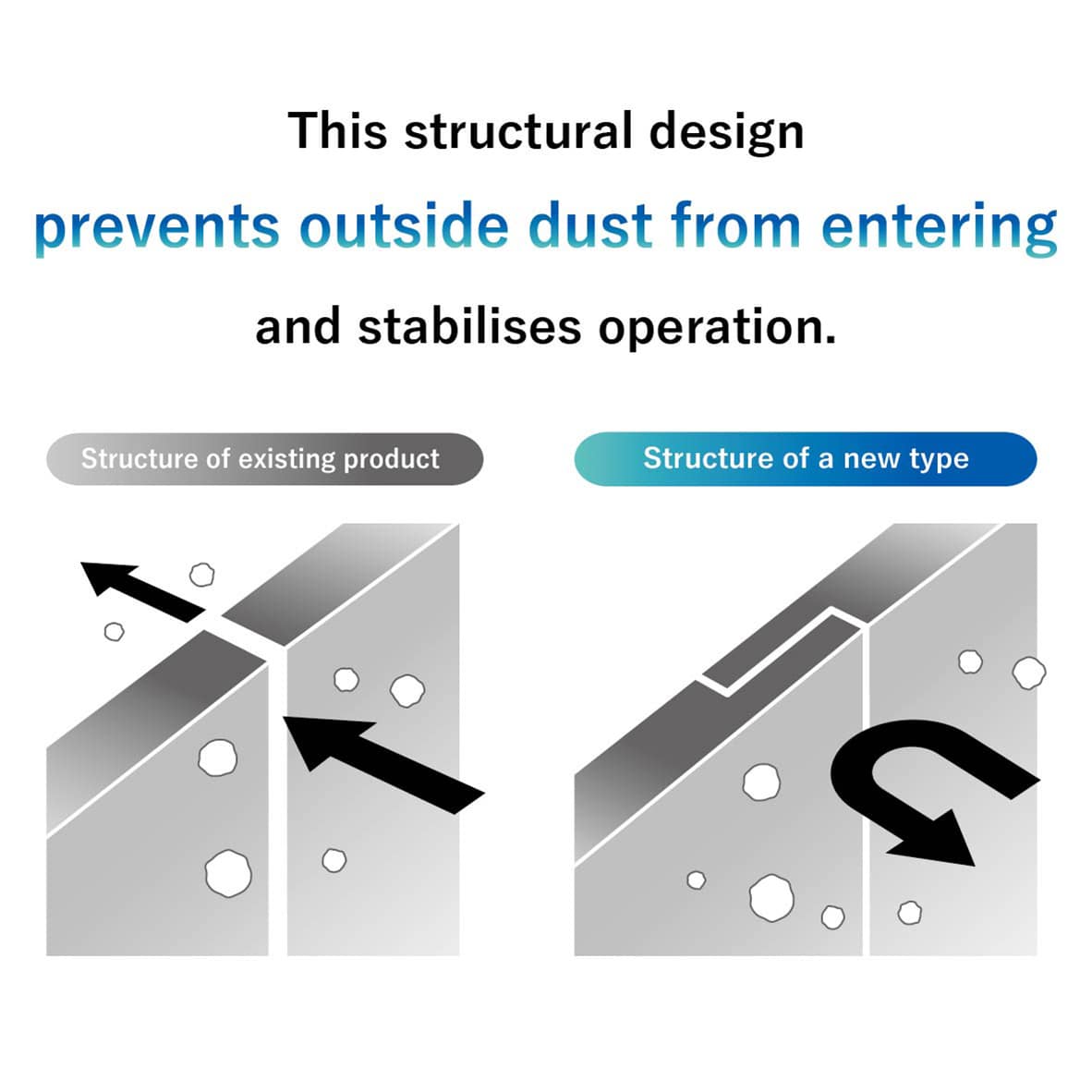

It has a tight-fitting structure, which eliminates the issues associated with magnetic starters.

Dust causes approximately half of all continuity problems, but SC-NEXT reduces the area of opening by 70% when compared to conventional products, and it also uses a revised fitting method.

This structural design prevents outside dust from entering and stabilises operation.

Consumable parts can be replaced to extend the life of the product.

Consumable parts may deteriorate before the end of the product's life expectancy, depending on how they are used in the field. The coil and contact can be replaced, avoiding the need to replace the entire product even if it is still functional. Product life is extended by replacing consumable parts.

Various other advances have also been made.

- Reducing the number of models makes management more efficient

- Pursuing a paperless system through the use of laser printing on nameplates

- Adoption of twin contacts with high contact reliability