Why had they decided to challenge?

TWIN Breaker Development Story

The breaker that was called impossible to create.

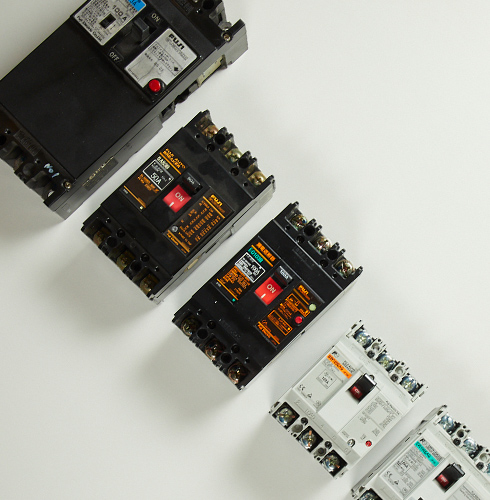

Our leading products are electromagnetic switches and TWIN breakers.

The electromagnetic switch that we produced for the first time in Japan was guaranteed its success from the beginning; whereas the breaker that we produced later was an additional product. Breaker was even called a burden product. What had the development team done?

The historical product, the miniaturized product that nobody thought of before has been established as the industrial standard afterwards; we simulate the development story of "Twin Breaker" based on interviews.

Interviewed in March 2018. Title and affiliation recorded were at the time of the interview.

"It's impossible." I wanted to topple the common sense.

"It's impossible." I wanted to topple the common sense.

- Aim for the second industry ranking from the very last start!

- "Isn't there any idea for a breakthrough?" At that time, Mr. Ohno who was in charge of the marketing for breakers as product manager of business division muttered.

Fuji Electric FA Components & Systems (at that time, Fuji Electric Co., Ltd.) had sent out various electrical equipments to the market, and among them, the "electromagnetic switch" was the top ranking from its launch and had been the main product of the company.

Fuji Electric started the breaker business as the second main product; the breaker market was already full. There were already 10 players in the market. Fuji Electric was the late joiner that launched the breaker from 1968 and only took up the market share by 10% and had suffered from the deficit.

For breaker market, the biggest manufacturer produced half of the total market and the rest only occupied 10% each and they were stuck. Mr. Ohno decided to expand the market share and become number two while boosting the profit; it was his job to reach these two goals.

- Looking for the right products and customers

Mr. Ohno first started market analysis. The breaker is delivered to control panel makers, machine makers, and electrical construction companies; the biggest customer was the distribution board maker, which accounted for about 60% of the market. The largest competitor was occupying more than 60% of the market; it was not easy to break down the strong player, but the market for the distribution panel makers with large volumes was attractive as well. Mr. Ohno decided to narrow down the target customer to power distribution panel makers.

Usually, compatibility with top manufacturer products were important for these components. Products of the same specifications as industry standards are cheaper to obtain. The cost advantage was a motivation for customers to change suppliers especially for the small and medium enterprises in distribution board industry; cost efficiency was the priority. You can sell compatible products at a lower price. However, Mr. Ohno thought that Fuji Electric should not take part in cost competitiveness.

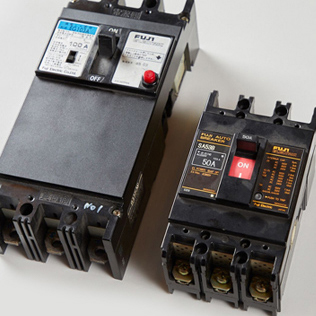

There was a case that provided a hint. It was the breaker, "DEPTH 60 Series", released by Fuji Electric in 1980. This is a breaker used for distribution boards which is always included in the power distribution, distribution facilities and integrated the depth of the product from 68 mm to 60 mm to be combined with other distribution board components. It did not greatly reduce the entire product dimension, but it aligned the depth size of the distribution board, thereby reducing the materials. For distribution board makers, this led to total cost reduction, so the market share increased from customers and became the starting point for Fuji Electric's breaker's share expansion. Product that meets customer needs is purchased. It was the belief.

- As the discovered principle is different, the size varies

We would like to explain the type of breaker here. The breaker is a protective equipment to prevent electrical accidents.

There are two major types of electric accidents.

a) Overload / short circuit accident: A fire caused by a large current. The range varies from several hundreds to several thousands. Causes include short-circuit of electric wires (wiring) or equipment failure.

b) Earth leakage / electric shock accident: Electric shock accident or leakage fires caused by breakage insulation or contact with charger. Current scale includes less than 100 to several hundred mA.

In both cases, the breaker's role is to detect an abnormal flow of electricity and to prevent accidents by instantly cutting off the supply of electricity to the failed part.

Therefore there are two types of breakers per the roles.

① Circuit breaker (wiring breaker) ... Mainly has the function to prevent type a accidents.

② Earth leakage circuit breaker (earth leakage breaker) ... It has the function to prevent accidents of both type a and b.

If the short-circuit fault detection in type a is set to about 800A, the electric shock accident detection in type b is about 30 mA. The detection accuracy is 25,000 times as wide as opening, and it is still technically impossible to create a sensor that detects both at the same time. So the sensors for these two types of breakers are completely different.

Mr. Ide who was in charge of developing circuit breaker says. "Since the structure of the detection part differs as the detection principle is different; its dimensions are completely different between the wiring breaker and the earth leakage circuit breaker, the earth leakage circuit breaker is much bigger. This was very common sense that no one in the industry thought that it could be possible to integrate the dimension of these two as to the different principles."

Mr. Ide who was in charge of developing the earth leakage circuit breaker, says. "There are many cases that you need to change the earth leakage breaker, even when the installation of the circuit breaker is planned at factories and buildings. In that case, the leakage current is larger than the wiring breaker. The internal side of the distribution board must be changed according to the circuit breaker.

Therefore the distribution board maker had to design the circuit breaker for wiring and shared distribution board with the base of the earth leakage circuit breaker and prepared a big board to change equipment models; which was not cost efficient.

Mr. Ohno paid attention to this demand. If the size of the earth leakage circuit breaker was same as the wiring circuit breaker, the size of the board could be made smaller and the design change could be minimized when replacing the components. If it were the same size,

Around the same time, Mr. Kobana, who was in charge of development, was told as a joke by a technician of a distribution and distribution board maker.

"It would be nice if the size of the earth leakage circuit breaker and wiring breaker were the same."

This idea changed significantly the destiny of Fuji Electric.

We did not allow compromise; and we achieved the "TWIN breaker"

We did not allow compromise; and we achieved the "TWIN breaker"

- "F Plan" - We decided not to chase the top manufacturer

The new breaker development project was started immediately, and members were gathered to develop a new product with the same size as the circuit breaker by miniaturizing the earth leakage circuit breaker. Focused on the basic plan, the possibility, the methodology and the impact on the market were examined.

Mr. Ohno speaks. "There was no need to re-appoint people, we already had something like a team. At that time, the Fukiage factory manufactured a distribution circuit breaker, and the Otawara factory developed a leakage breaker, and we could communicate with each other."

Mr. Kobana adds. "Since we had the top market share product, the electromagnetic switch manufactured by Fuji Electric Company, we wanted to produce another successful product. We worked on breakers with different departments; from sales, planning, development to manufacturing, we had a feeling that we wanted to have more support from customers."

Ten people were involved in the project, which was then called "F Plan". No matter of the working years, we had numerous very frank meetings. Although we had different opinions, our mission to "create a new circuit breaker" had profoundly created the solidarity of the team.

There were times of severe discussion as the idea was nonsense. "Just make it the same height?" "No, it does not make sense unless we make exactly the same dimensions." The discussion took a long time. At that time, the biggest competitor released a breaker with amazing performance due to a significant model change. Speaking from the common sense of the industry, the most important thing for industrial products was to have compatibility with products offered by top manufacturers. "Is it compatible with this one?", Mr. Kobana roared his voice when such a voice came up. "It does not matter if we the challenger does the same thing as the top manufacturer, it does not matter whether we win the market. It's that there are customers who need our hands, we just respond to them."

- 1 mm and 1 mm of defense

At that time, Fuji Electric launched products of a wide variety of series, so the production line was increasing. As production lines expanded, the cost of course increased. If the dimensions of the earth leakage circuit breaker and wiring breaker were the same, it becomes possible to manufacture on the same line. Only one type of conveying was sufficient. To break the common sense of the circuit breaker it involved the design departments of both Ohtawara and Fujibami factories.

Mr. Ide who was leading the earth leakage circuit breaker team says. "As a technical member of the earth leakage circuit breaker, it was a big challenge how small the part that detects the earth leakage as the zero-phase current transformer (ZCT) to be made small, and even if a large current of 500 amperes instantaneously flows, it does not malfunction. We must guard the sensor so that it does not malfunction, and by changing the specification it can correspond to all ranges from 100 volts to 400 volts, we also did not forget to consider various environment factors that this could be used in."

Mr. Kobana, who was involved in the development of a circuit breaker, recalls.

"Besides miniaturizing all parts, it was necessary to develop a new mechanism for the short-circuit current interruption part, and to share parts among both circuit breakers. The design stage was a match of 1 mm unit dimension because we reduced the size by as much as 60% with 225A earth leakage breaker which was downsized. I narrowed it down to the very tiny size that fulfills the function as a circuit breaker. "

"I wondered whether we could achieve what the big makers could not have". We worked hard to take off all these doubts and we re-created all these common senses. Eventually, people from the sales department and the business department also joined, and when the organizational movement was created for the "F Plan", no one doubted the birth of historical products.

The Electrical Construction Industry Exhibition where we received the honor of "the product once in 10 years"

The Electrical Construction Industry Exhibition where we received the honor of "the product once in 10 years"

- " TWIN breaker" - Two circuit breakers that resembles twins

The announcement of the new product was decided for the '90 electric construction industry exhibition. Production was carried out at a rapid pitch for the day. Mr. Kobana speaks. "The earth leakage circuit breaker has succeeded in compactness with the desperate efforts of engineers from Mr. Ide's team, so we could not be defeated. The power distribution circuit breaker instantly turned on the plasma arc as high as 100,000A. In order to make materials that could withstand such high currents, we developed new technologies such as silver plating with carbon. It was repeated trial and error."

Mr. Ide adds. "By testing and incorporating various technologies, our development technology has improved at a stroke, for example, it was the first time that we adopted flexible printed wiring that is superior in pressure resistance and heat resistance and that can be flexibly used. I asked the Japanese swordsmith to make prototypes of complex contact parts ... Anyhow, I tried various materials and methods without being bound by the methodology and method that I had been using. "

The product name came from the American movie "Twins" which was popular at that time. The naming expresses the appearance of two types of breakers of the same size is still a monopoly patent of Fuji Electric.

- In the Electrical Construction Industry exhibition, we went viral.

The headline that "Fuji Electric, the industry top manufacturer appeared" went out in the industry magazine the next day of the Electric Construction Industry exhibition. By the evaluation at the exhibition, every single person cited TWIN breaker as the top item. We received a lot of orders from all over the country, the production side screamed for its business.

Mr. Kozaku continues."We invited customers from the entire country to the Fukiage factory and carried out briefing sessions. When a customer told me that "you became a double sword of electromagnetic switch and breaker", I was very happy."

The market impact that the TWIN breaker brought to the industry could be summarized with the following action of the domestic top manufacturers that normally do not follow the products of the second-tier manufacturer. They just launched a new product to the market, but they succeeded in creating the similar product just in a year and a half. Mr. Kobana who thought it could take up to 3 years was very surprised. From the story itself, the TWIN breaker had very large impact on the entire industry makers.

Thereafter, although competitors also provide similar product, Fuji Electrics could expand the market share formally 10% to its double size.

Monozukuri - the challenging spirit made it possible

Monozukuri - the challenging spirit made it possible

- "I never thought I couldn't do it ", everything was created from the trust.

TMr. Ohno who served as the product manager says. "My job is to know all of the products in charge and solve problems one by one while trying to increase profit. It was my job to conduct market research, marketing development, sales, development, production and all the adjustments to promote the business. So my work was satisfying." "Mr. Ohno successfully lead as a product manager," Mr. Ide and Kozu also added loudly. Mr.Ohno laughs. "I never worried if I could really do it. " However, I was cautious about making a mold. I had to make a mold at a certain stage, and it was very expensive, and if I fail it would cause a lot of loss. Still, if it doesn't go well, I had to survive. I guess that's why you trust the team so much. "

- The foundation and the spirit that created new standards

Mr. Ohno taught that the fact that the TWIN breaker could be commercialized was because its foundation was already provided by Fuji Electric. "An electromagnetic switch must be able to withstand opening and closing as many times as, for example, 3 million times, so even if only the structure of the machine is considered, it must be understood from the essence of the material. In most manufacturers it is usual that designers do not know the material, but our company has advantage of having a department specialized in research and development of materials." Mr. Kobana continues. "Manufacturers mostly outsource material selection and evaluation. However if it is outsourced, it becomes complicated and time-consuming. The TWIN breaker was produced because Fuji Electric provided concurrent engineering foundation ; from planning, designing to material development and production, manufacturing "

The TWIN breaker series still stands as one of the main products of Fuji Electric FA Components & Systems.

Interview

Q: Based on your own experience, could you please share with us what is important for commercialization and development of new products, or a message for active product planning and product development?

- Kobana:

- If it's a top-share product, I would like you to become the majestic top sumo wrestler. In other words, we should develop products that make standardization of the industry as a whole, or create new standards in the industry. In another words, if it is a challenge, you should absolutely stop copying the top manufacturer's product. It is good even in a small place to persistently devise ingenuity and create original improvement. Also take good advices even it could requires a change in design. However, if you make a change that loses the essence of the product, thoroughly discuss it without compromising. These are things I learned from my own experience.

- Ide:

- Since the development of the TWIN breaker, I've seen a series of developments, and it's better for engineers in development to see how the end users are using the product. Particularly when a product is malfunctioning. By doing so, you can find the next task. Of course, new technologies will be available in both material technology and development technology, so it is also important to disseminate insights into such areas. The technological development accumulated in the customer's site and advanced technological methods will help grow engineers.

- Ohno:

- In terms of the planning department, practice the duties of the product manager firmly. It all depends on that. From my experience it was good to observe everything with a bird's eye view, and not limit it to the target product.

Not only breakers but also where the power distribution and distribution boards are used, how do you see your company from outside, what about from a joint venture partner perspective? To put it more, how will the world change? For that, we need to meet various people, get various information, and have the ability to judge. Development, Sales, Production, Customers, Competitors ... ... It is quite easy to get more ideas when we talk with many different people.