Kelestarian

Penggunaan Sumber Air yang Cekap

Selaras dengan Dasar Perlindungan Alam Sekitar Asas dan Wawasan Alam Sekitar 2050 kami, Fuji Electric berhasrat untuk menyumbang kepada pencapaian masyarakat berorientasikan kitar semula. Untuk mencapai matlamat ini, kami mempromosikan aktiviti dengan matlamat merealisasikan ekonomi bulat di seluruh rantaian bekalan kami.

Penggunaan Sumber Air yang Cekap

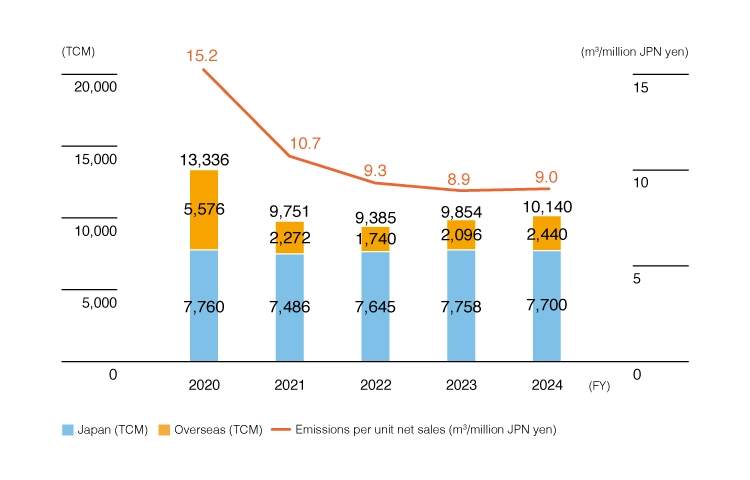

Isu kehabisan sumber air telah menjadi kebimbangan global. Oleh itu, selain mematuhi piawaian air sisa, Fuji Electric telah menetapkan sasaran untuk mengurangkan pengambilan air bagi setiap unit jualan untuk menggalakkan penggunaan sumber air yang cekap. Pada fiskal 2024, pengambilan air seluruh syarikat kami meningkat sebanyak 2.8% tahun ke tahun, terutamanya disebabkan peningkatan pengeluaran semikonduktor di Kilang Malaysia kami. Namun begitu, pengambilan air seluruh syarikat kami bagi setiap unit jualan kekal pada 900 m³ setiap 100 juta yen.

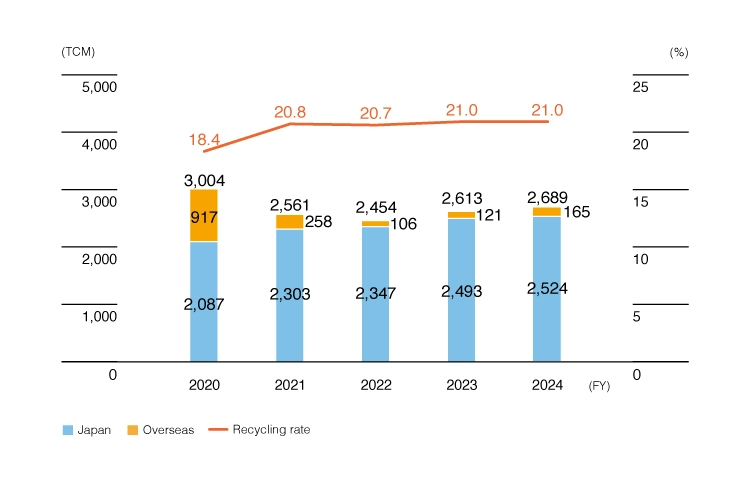

Untuk menggunakan sumber air dengan lebih cekap, kami juga telah memajukan usaha kitar semula air. Untuk meningkatkan kadar kitar semula kami, kami memasang kemudahan pengeluaran air kitar semula tambahan di Kilang Matsumoto, yang mula beroperasi pada Disember 2023. Walau bagaimanapun, disebabkan peningkatan pengeluaran di Kilang Malaysia kami, kadar kitar semula air untuk fiskal 2024 kekal pada 21.0%, sama seperti tahun sebelumnya.

-

Nota

-

Kami mengira "isipadu penggunaan air" dan "kadar kitar semula" menggunakan formula berikut:

Isipadu penggunaan air = isipadu pengambilan air + isipadu air kitar semula

Kadar kitar semula = isipadu air kitar semula / isipadu penggunaan air

-

Nota

-

Jepun — isipadu air paip yang dibeli + isipadu air industri yang dibeli + isipadu air bawah tanah yang digunakan (hanya air bawah tanah * digunakan dalam aktiviti pengeluaran)

Luar negara - Air industri

-

*

-

Isipadu air bawah tanah tidak termasuk air bawah tanah yang digunakan untuk pembersihan tanah, untuk tujuan pertanian, atau untuk mencairkan salji.

Penilaian Risiko Tekanan Air

Fuji Electric telah menjalankan penilaian menggunakan Aqueduct 4.0* untuk mengenal pasti sama ada mana-mana tapak pengeluaran kami di seluruh dunia terdedah kepada risiko tekanan air. Akibatnya, tapak tertentu di rantau Asia telah dikenal pasti mempunyai risiko tekanan air yang tinggi; bagaimanapun, telah disahkan bahawa jumlah pengambilan air di tapak ini adalah agak rendah.

-

*

-

Aqueduct: Peta risiko air global yang diterbitkan oleh World Resources Institute (WRI).

Kilang Shenzhen kami di China, yang menghasilkan fotoreseptor, dinilai dengan skor Aqueduct 4.0 2 daripada 5, menunjukkan kawasan berisiko rendah. Walau bagaimanapun, rantau ini tidak mempunyai sungai yang besar, dan kestabilan bekalan air secara amnya dianggap sebagai satu cabaran kerana peningkatan aktiviti ekonomi dan pertumbuhan penduduk. Malah, dari 2021 hingga 2022, kemarau teruk berlaku akibat fenomena La Niña.

Dengan mengambil kira syarat ini, syarikat kami telah mengklasifikasikan Kilang Shenzhen sebagai tapak senarai pantau berisiko air dan telah melaksanakan langkah-langkah berikut:

-

1.

Pemasangan tangki simpanan air untuk meminimumkan kesan pengeluaran semasa gangguan air sementara

-

2.

Pengenalan kemudahan untuk mengitar semula air sisa (mencapai kadar kitar semula 80%, melepasi sasaran 70% yang dipersetujui dengan bandar Shenzhen)

Melalui usaha ini, kami sedang berusaha untuk mengukuhkan sistem bekalan air yang stabil di wilayah Shenzhen sepanjang tahun.

-

Nota

-

Penggunaan air: Isipadu Air yang dibeli + dikitar semula

-

Nota

-

Nisbah risiko air: Isipadu air yang dibeli (Kilang Shenzhen) / Jumlah pengambilan air Kumpulan

Status pengurusan pengambilan air

Di Fuji Electric, sebahagian besar kemudahan pengeluaran kami terletak di taman perindustrian, yang dibekalkan dengan kedua-dua air industri dan air paip boleh diminum; beberapa kemudahan kami juga menggunakan air bawah tanah. Kami menyediakan laporan tahunan tentang jumlah pengambilan air bawah tanah kepada pihak berkuasa yang berkaitan, dan berusaha untuk memastikan kami menggunakan sumber air tempatan dengan cara yang sesuai. Kami menggunakan air bawah tanah di 15 daripada 19 kemudahan kami di Jepun, dan ia menyumbang 53.7% daripada jumlah pengambilan air kami. Pada masa lalu, pengambilan air bawah tanah telah mengakibatkan penurunan tanah di Jepun; hari ini, bagaimanapun, kerajaan telah menetapkan piawaian untuk memastikan jumlah pengambilan air diuruskan dengan sewajarnya. Sehubungan itu, isu sosial yang disebabkan oleh pengambilan air hampir tidak wujud.

Hanya satu daripada 14 kemudahan luar negara kami menggunakan air bawah tanah, dan ia menyumbang hanya 0.05% daripada jumlah pengambilan air luar negara kami. Di Kilang Matsumoto, Yamanashi, Tsugaru, dan Malaysia, yang menggunakan isipadu air yang besar terutamanya dalam proses semikonduktor bahagian hadapan mereka, dan di Kilang Shenzhen kami mempromosikan kitar semula air sebagai satu cara untuk mengawal dan mengurus isipadu pengambilan air.

Di tapak lain juga, kami bertindak pantas dalam kes di mana penilaian kesan alam sekitar ISO 14001 mengenal pasti kesan ketara akibat penggunaan air. Selain daripada penjimatan air dalam aktiviti harian kami, kami juga berusaha untuk memastikan pengesanan awal dan pembaikan kebocoran air, melabur dalam sistem kitar semula air dan memasang paip di atas tanah untuk tujuan visualisasi.

Status pengurusan air sisa

Kami mengawal ketat air sisa di kilang yang menggunakan bahan kimia. Kami juga telah menetapkan piawaian kami sendiri untuk pengurusan air sisa, yang lebih ketat daripada yang dimandatkan secara sah. Jika keabnormalan dikesan dalam sistem rawatan air sisa, kami mempunyai kakitangan pembaikan pemastautin di tempat untuk bertindak balas dengan segera. Jika kami mengesan pelarasan pH yang tidak mencukupi atau masalah yang serupa, saluran saliran kami ditutup secara automatik untuk mengelakkan air sisa yang tidak memenuhi piawaian rasmi daripada dibuang ke luar. Air sisa substandard ini disimpan di dalam takungan saliran sehingga pemulihan selesai.

Dengan menguruskan air sisa secara ketat dengan cara ini, kami berusaha untuk meminimumkan kesan aktiviti kami terhadap ekosistem.

Usaha untuk menggunakan air secara berkesan di tapak pengeluaran kami

Kilang Matsumoto menggunakan sejumlah besar air dalam proses semikonduktor bahagian hadapannya, jadi ia berusaha untuk mengitar semula air sebagai satu cara untuk mengurangkan beban alam sekitarnya. Terima kasih kepada kemudahan pengeluaran air kitar semula baharu yang mula beroperasi pada Disember 2023, pada fiskal 2024 Kilang meningkatkan penggunaan air kitar semula sebanyak 10.5% berbanding fiskal 2022, dan juga meningkatkan kadar kitar semulanya sebanyak 0.6%. Melangkah ke hadapan, kami akan terus memperkukuh kitar semula air kami dan aktiviti pengurangan pengambilan air kami.

Topik

Penggunaan sumber air yang cekap di kilang Matsumoto

Penggunaan sumber air yang cekap di kilang Matsumoto

Kilang Matsumoto kami, tempat kami membuat wafer semikonduktor, menggunakan sejumlah besar air tulen dalam proses fabrikasi wafer dan banyak air untuk menyejukkan peralatan pengeluaran. Oleh itu, adalah penting untuk kita mengurangkan penggunaan air dan menggunakan sumber air kita dengan berkesan.

Inisiatif kitar semula air tulen:

Air sisa daripada proses pembuatan diasingkan dan bahagian yang agak berkualiti tinggi dikitar semula sebagai air mentah untuk pengeluaran air tulen.

Untuk meningkatkan pemulihan air sisa daripada proses pencucian, kami telah berjaya membuat penapis karbon bioaktif dengan Microbacteriaceae, yang terkenal dengan keupayaan rawatan bahan organik, dan dengan itu meningkatkan kadar pemulihan. Untuk air sisa yang mengandungi fluorin, yang berbahaya kepada alam sekitar, kami telah memperkenalkan sistem pemulihan air sisa khusus yang menggunakan membran osmosis songsang untuk menumpukan air sisa dan mengurangkan isipadunya. Selain itu, air bersih yang telah melalui membran digunakan semula sebagai air mentah untuk membuat air tulen.

Mengurangkan penggunaan bahan kimia di kemudahan rawatan asid hidrofluorik:

Proses penulenan air memerlukan penjanaan semula resin penukar ion secara tetap, yang menghasilkan campuran air sisa berasid dan beralkali. Di Fuji Electric, kami sebelum ini meneutralkan air sisa ini dan, selepas rawatan terminal, membuangnya ke dalam sistem kumbahan awam. Berhasrat untuk mengurangkan penggunaan bahan kimia, kami telah mencipta dan memperkenalkan sistem kitar semula air sisa baharu yang memisahkan larutan beralkali berkepekatan tinggi daripada air buangan, dan menggunakan semula larutan beralkali ini untuk membuat pelarasan yang diperlukan pada tahap pH bagi peralatan rawatan asid hidrofluorik kami. Ini telah membolehkan kami mengurangkan jumlah bahan kimia yang digunakan, serta kos keseluruhan.

Membina sistem kitar semula air sisa baharu

Sebagai tambahan kepada sistem kitar semula air sisa Pengurusan Air Bersepadu (IWM) sedia ada kami, pada fiskal 2023 kami memulakan operasi sistem kitar semula air sisa baharu. Sistem baharu ini mampu mengitar semula dua kali ganda isipadu air sisa sistem sedia ada dan, terima kasih kepada pelbagai penambahbaikan, air terawat mempunyai kualiti yang cukup tinggi yang boleh digunakan untuk penyaman udara. Ini telah membolehkan kami menyokong peningkatan pengeluaran produk Si dan produk SiC. Melangkah ke hadapan, kami akan terus mempertimbangkan cara untuk menggunakan sumber air dengan cekap.