Kelestarian

Mencapai Masyarakat Dekarbon

Di Fuji Electric, kami sedang berusaha untuk mencapai neutraliti karbon merentasi rantaian bekalan; ini selaras dengan Wawasan Alam Sekitar 2050 kami, yang kami rumuskan sebagai tindak balas kepada peralihan global ke arah neutraliti karbon dan matlamat penyahkarbonan kerajaan Jepun. Untuk membantu kami mencapai Matlamat Fiskal 2030 kami, yang berfungsi sebagai matlamat sementara untuk Wawasan Alam Sekitar kami, kami sedang berusaha untuk memastikan bahawa pelbagai langkah dimasukkan ke dalam pelan tindakan setiap jabatan kami.

Pelan Tindakan untuk Mengurangkan Pembebasan Gas Rumah Hijau

Masyarakat telah mencapai kemajuan besar dalam mencegah pemanasan global sejak menerima pakai Perjanjian Paris pada Disember 2015. Perjanjian itu menetapkan bahawa purata kenaikan suhu di seluruh dunia mesti dikekalkan secukupnya di bawah 2°C berbanding tahap pra-perindustrian, dan usaha mesti dilakukan untuk mengehadkan peningkatan kepada 1.5°C. Berdasarkan latar belakang ini, Fuji Electric menetapkan sasaran pada fiskal 2018 untuk mengurangkan pelepasan gas rumah hijau (Skop 1+2) dalam aktiviti pengeluaran menjelang fiskal 2030, dan merumuskan “Wawasan Alam Sekitar 2050” pada fiskal 2019.

Walaupun begitu, trend sosial telah meningkat lebih cepat daripada yang kami jangkakan pada mulanya. Sebagai contoh, pada tahun 2020, negara utama di seluruh dunia mula meningkatkan sasaran pengurangan pelepasan gas rumah hijau mereka. Di tengah-tengah trend sosial yang bergerak pantas ke arah penyahkarbonan ini, Fuji Electric menyemak sebahagiannya "Wawasan Alam Sekitar 2050" pada 2021, mengumumkan bahawa ia akan menyasarkan neutraliti karbon dalam keseluruhan rantaian bekalannya. Di samping itu, kami juga menyemak semula sasaran fiskal 2030 kami pada Mac 2022, meningkatkan sasaran pelepasan gas rumah hijau dalam aktiviti pengeluaran dan mewujudkan sasaran baharu untuk mengurangkan pelepasan gas rumah hijau (Skop 1+2+3) di seluruh rantaian bekalan.

Selain itu, kami memperoleh pensijilan untuk "tahap 1.5°C" oleh SBTi (Science Based Targets Initiative), sebuah inisiatif antarabangsa, pada tahun 2022 untuk sasaran pengurangan baharu kami untuk Skop 1+2 dan Skop 3.

Mengurangkan Pelepasan Gas Rumah Hijau Semasa Pengeluaran

Pengurangan Jumlah Pelepasan Gas Rumah Hijau

Fuji Electric mengambil pelepasan gas rumah hijau (GHG) sebagai metrik untuk menilai aktiviti kami untuk merealisasikan masyarakat dengan pelepasan karbon bersih-sifar. Kami mentakrifkan pelepasan gas rumah hijau sebagai jumlah CO 2 yang dipancarkan melalui penggunaan tenaga dan gas rumah hijau seperti HFC, PFC, SF 6 dan NF 3 yang dikeluarkan dalam proses pengeluaran.

Malah sebelum merumuskan Wawasan Alam Sekitar 2050, kami sedang berusaha untuk mengurangkan pelepasan GHG daripada aktiviti pengeluaran.

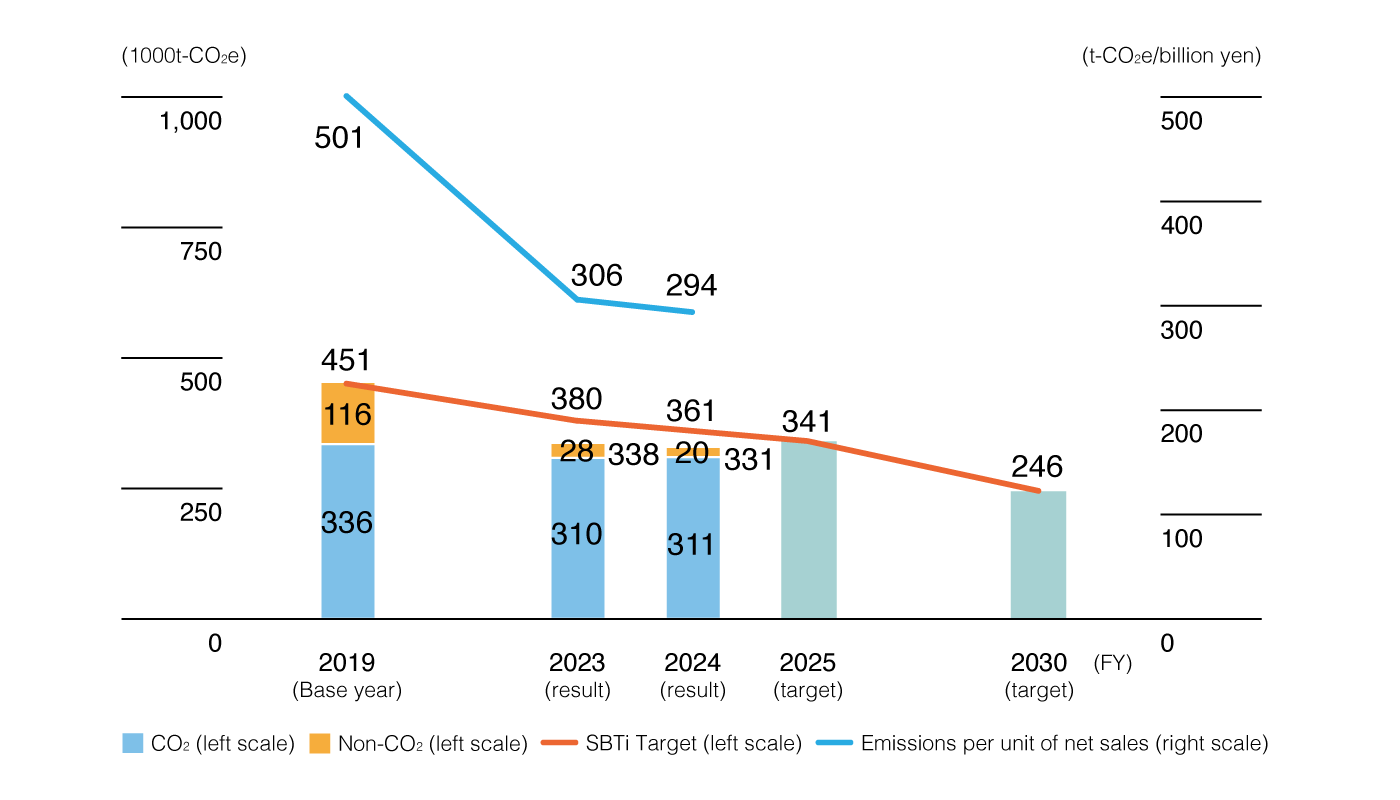

Sasaran yang ditetapkan untuk fiskal 2030 menyasarkan pengurangan lebih daripada 46% setara CO 2 pada keputusan fiskal 2019, dan pengurangan 85% daripada fiskal 1990 (tahun asas global untuk Protokol Kyoto).

Inisiatif pengurangan pelepasan gas rumah hijau dan hasil dalam aktiviti pengeluaran (fiskal 2023)

1.<Skop>

Julat pengagregatan adalah bersamaan dengan 95.2% daripada keseluruhan Kumpulan (angka peratusan merujuk kepada aktiviti pengurusan alam sekitar kami)

(1)Jepun: Semua tapak pengeluaran dan anak syarikat pengeluaran yang disatukan

(2) Luar Negara: Anak syarikat pengeluaran yang disatukan tidak termasuk dua tapak yang tidak diperakui di bawah ISO 14001

2.<Pekali kuasa>

Jepun:

Untuk tahun fiskal 2023 dan 2024, pekali kuasa diperoleh daripada "Faktor Pelepasan Terlaras untuk Syarikat Bekalan Elektrik," seperti yang diterbitkan dalam Faktor Pelepasan untuk Kuasa yang Dibekalkan oleh Syarikat Utiliti Elektrik, yang dikeluarkan bersama oleh Kementerian Alam Sekitar dan Kementerian Ekonomi, Perdagangan dan Industri.

Untuk tahun fiskal 2019 hingga 2022, pekali kuasa dikira dengan merujuk kepada Komitmen KEIDANREN kepada Masyarakat Rendah Karbon; pada fiskal 2022, ini menghasilkan pekali kuasa 0.436 kg-CO₂e/kWj.

Luar negara:

Pekali kuasa, seperti yang ditakrifkan dalam Faktor Pelepasan IEA 2024, adalah berdasarkan data khusus negara terkini, dengan merujuk kepada tahun 2022.

3.<Pengiraan Skop 2>

Skop 2 pelepasan di Jepun telah dikira mengikut kaedah berasaskan pasaran sejak tahun fiskal 2023.

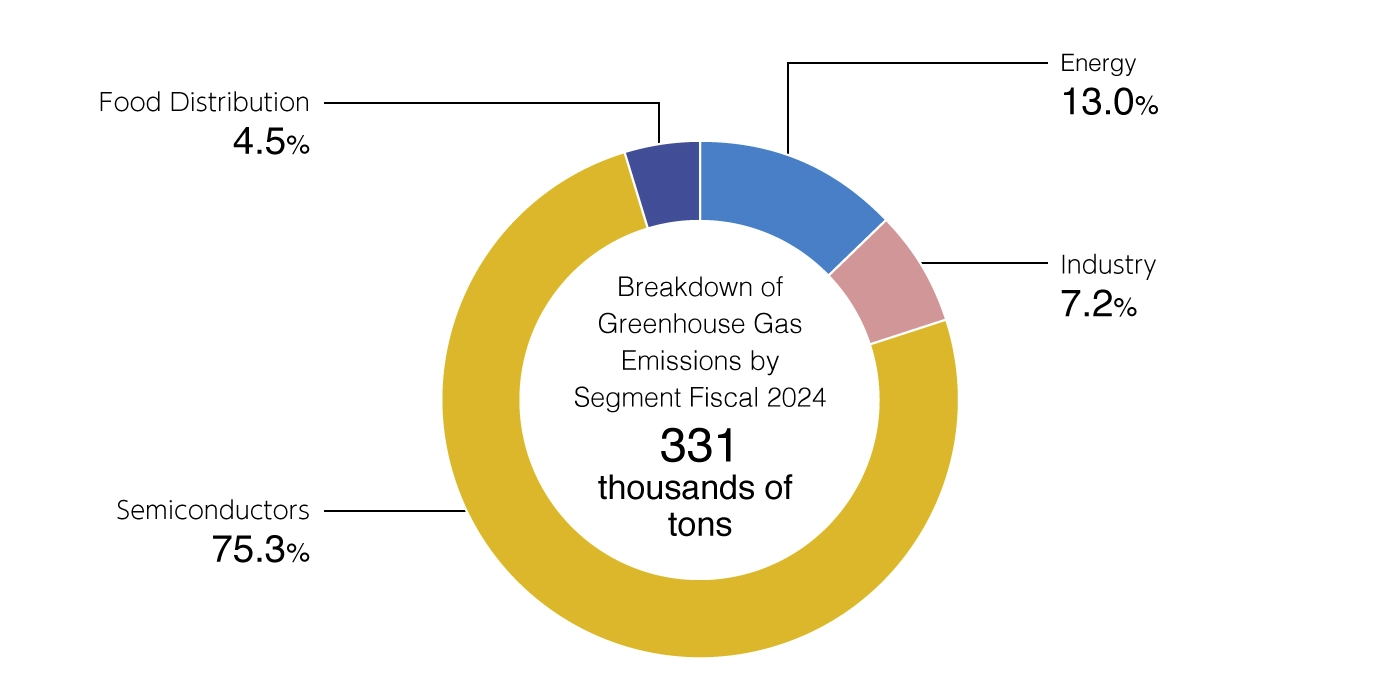

Pelepasan gas rumah hijau sebenar dalam aktiviti pengeluaran pada fiskal 2024 ialah 331 ribu tan. Pencapaian ini adalah kira-kira 8% di bawah sasaran untuk tahun fiskal (di bawah 360 ribu tan). Memandangkan nilai sasaran ini sepadan dengan nilai pelan tindakan SBT (nilai untuk fiskal 2023 pada garis lurus yang menghubungkan nilai asas untuk fiskal 2019 dan nilai sasaran untuk fiskal 2030), boleh dikatakan bahawa kami kini berada di landasan yang betul untuk mencapai keputusan yang akan memenuhi rancangan SBT.

-

Aktiviti penjimatan tenaga (tenaga suria, pemasangan lampu kecekapan tinggi, penyaman udara, dll.): -2 ribu tan (0.6%)

-

Penggantian gas rumah hijau: -4 ribu tan (1.2%)

-

Kesan pemasangan tenaga solar baharu: -4 ribu tan (1.2%)

-

Pembelian kedua-dua sijil tenaga boleh diperbaharui dan tenaga boleh diperbaharui -13 ribu tan (3.9%)

Jumlah pengurangan pelepasan berdasarkan ukuran: -23 ribu tan (6.9%)

Pelepasan Gas Rumah Hijau: Keputusan dan Langkah Masa Depan

CO 2 yang dikeluarkan semasa pengeluaran berada di bawah pelepasan Skop 1 dan Skop 2.

-

Skop 1:Pelepasan gas rumah hijau langsung oleh syarikat pelapor itu sendiri.(cth. pembakaran bahan api, proses perindustrian)

-

CO₂ dipancarkan terus dari kilang akibat pembakaran bahan api semasa penjanaan kuasa penjanaan bersama, dandang, relau pengeringan, dsb.

-

Empat jenis gas rumah hijau yang dikeluarkan secara langsung daripada proses pengeluaran

-

-

Skop 2:Pelepasan tidak langsung daripada penggunaan elektrik, haba atau wap yang dibekalkan oleh orang lain.

Sehingga kini, kami telah berusaha untuk mengurangkan pelepasan CO 2 terutamanya melalui aktiviti penjimatan tenaga yang bertujuan untuk meningkatkan kecekapan tenaga. Walau bagaimanapun, menjadi jelas bahawa kami tidak dapat memenuhi sasaran jangka sederhana kami dengan hanya mengembangkan langkah penjimatan tenaga konvensional. Atas sebab ini, kami telah menyemak kriteria pelaburan kami dan memasukkan pelaburan dalam penghawa dingin berkecekapan tinggi dan lampu LED ke dalam pelan pembaharuan lima tahun untuk setiap kilang untuk mencapai sasaran pengurangan kami.

Pada fiskal 2022, kilang yang dikaitkan dengan bahagian semikonduktor kami mula membeli tenaga boleh diperbaharui dan sijil tenaga boleh diperbaharui secara percubaan. Akibatnya, bahagian tenaga boleh diperbaharui dalam jumlah penggunaan kuasa kami meningkat kepada 9.1% pada fiskal 2024, mengurangkan pelepasan CO 2 sebanyak kira-kira 6,000 tan. Untuk memastikan bekalan tenaga boleh diperbaharui yang stabil, kami juga menandatangani tiga Perjanjian Pembelian Kuasa (PPA) pada tahun fiskal yang sama.

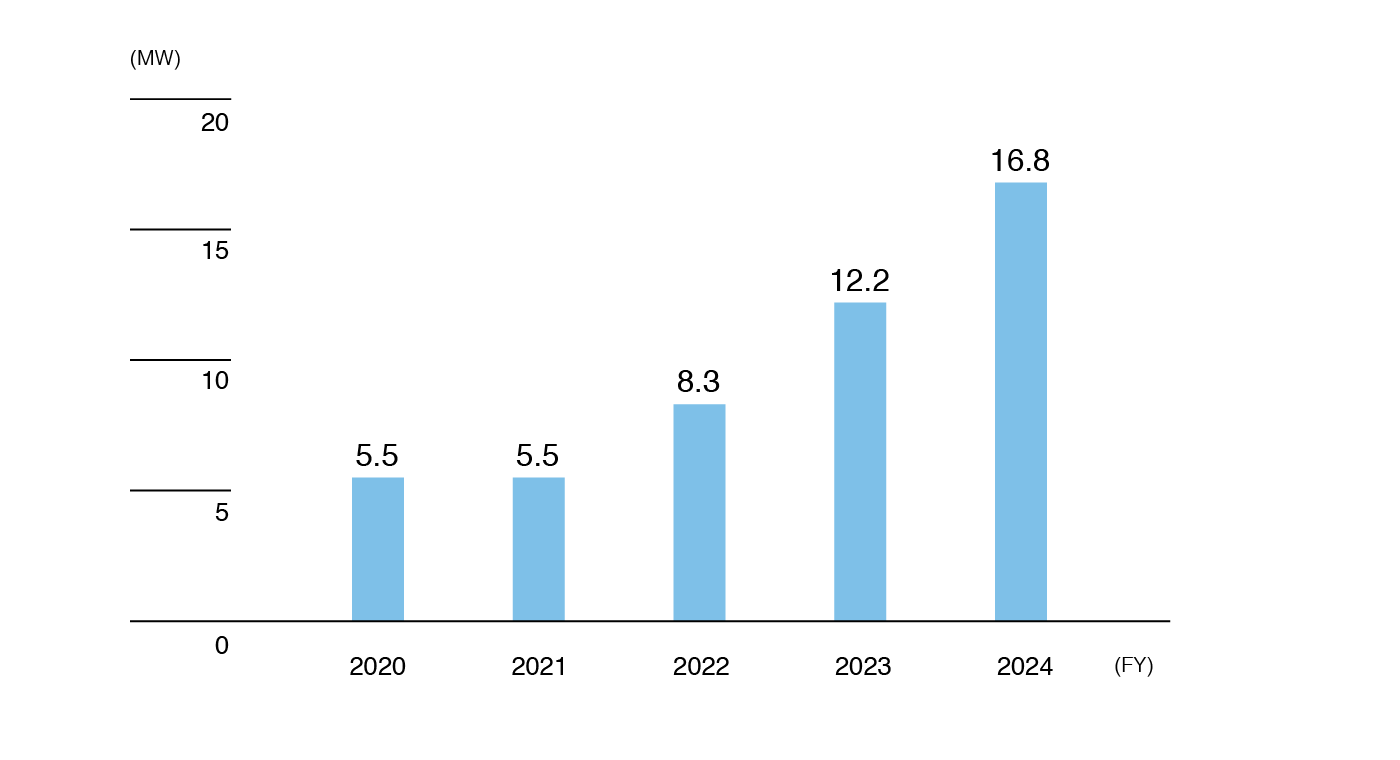

Sebagai langkah khusus untuk mencapai matlamat "sasaran Fiskal 2030 kami (untuk mengurangkan pelepasan gas rumah hijau kami)" dalam "Wawasan Alam Sekitar 2050", kami menyasarkan untuk memaksimumkan penggunaan peralatan penjanaan tenaga suria di tapak pengeluaran kami di Jepun dan luar negara, dan sedang memasang peralatan di atas bumbung bangunan kilang melalui perjanjian pembelian kuasa sendiri (PP-partA).

Di Jepun, Kilang Chiba, Kilang Mie, dan kilang Fukiage dan Otawara Fuji Electric FA Components & Systems Co., Ltd., memulakan operasi kemudahan penjanaan tenaga solar dengan jumlah kapasiti 3.3 MW pada fiskal 2024.

Pada fiskal 2025, Kilang Kobe dan Wilayah Saitama dijadualkan untuk memulakan operasi kemudahan penjanaan tenaga solar dengan kapasiti maksimum 1.0 MW.

Di luar negara, Fuji SMBE Co., Ltd. memulakan operasi dengan kapasiti 0.7 MW, dan Fuji Electric (Shenzhen) Co., Ltd. memulakan operasi dengan peningkatan kapasiti 1.3 MW berikutan pengembangan pada fiskal 2024.

Unit: MWj

Untuk mengurangkan jumlah gas rumah hijau yang dikeluarkan semasa pengeluaran, pada 2022 Fuji Electric melancarkan Projek Promosi Tenaga Boleh Diperbaharui, yang bertujuan untuk memasang kemudahan penjanaan tenaga solar di semua pangkalan pengeluaran syarikat. Projek ini diterajui oleh jabatan perniagaan tenaga baharu dengan pengetahuan memasang tenaga boleh diperbaharui, yang bekerjasama dengan setiap pangkalan pengeluaran kami untuk merangka pelan pemasangan.

Secara khusus, 18 pangkalan pengeluaran di Jepun dan dua pangkalan di luar negara mula mempertimbangkan pemasangan kemudahan penjanaan tenaga solar. Pada fiskal 2024, kami memasang kira-kira 5,300 kW di lima tapak domestik dan dua tapak di luar negara, dan memulakan operasi. Kami menyasarkan untuk menjana sekitar 32 juta kWj setiap tahun menjelang fiskal 2027 dan akan terus menggalakkan penggunaan kemudahan tenaga solar selanjutnya.

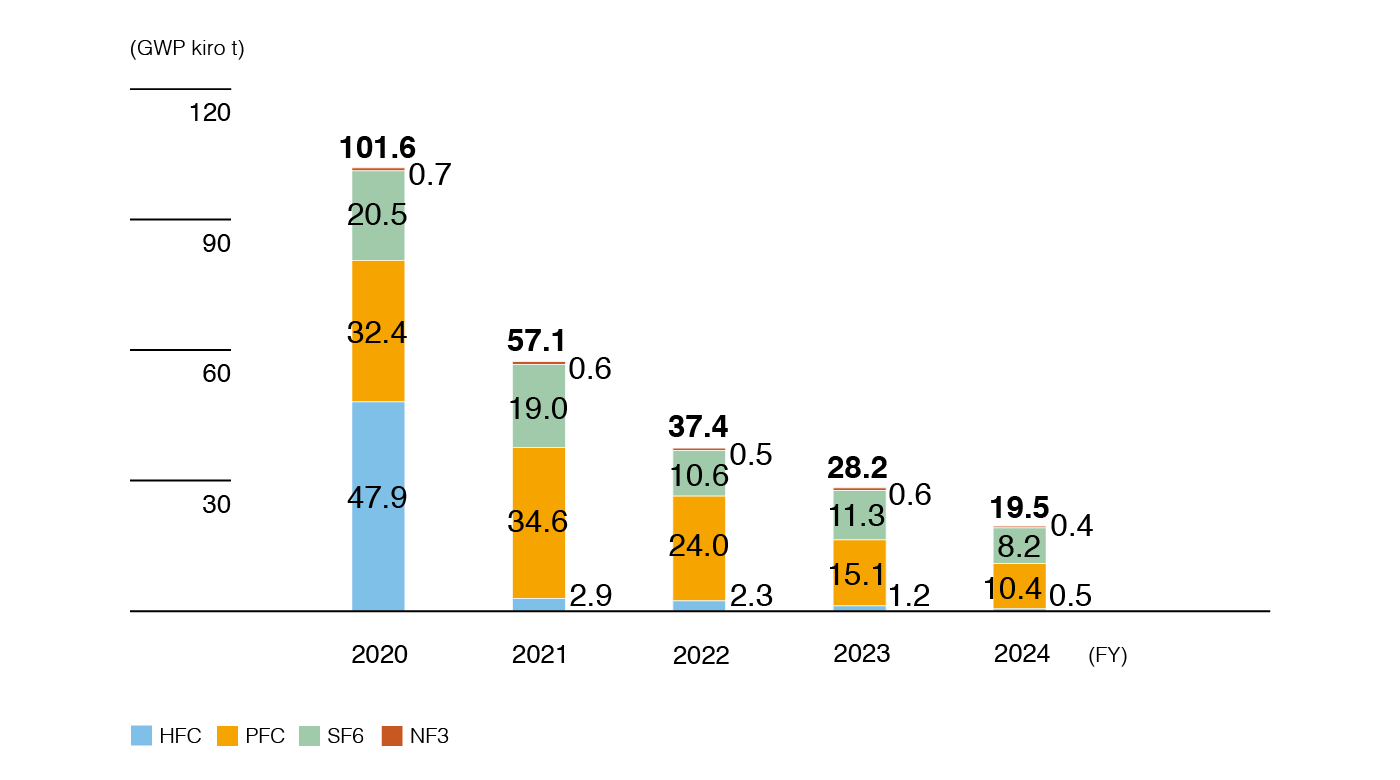

GHG yang kami gunakan dan kegunaan utamanya adalah seperti berikut.

-

HFC (pengganti CFC): Digunakan sebagai penyejuk, pelarut, dan untuk pengelasan kering semikonduktor

-

PFC (perfluorocompounds): Digunakan untuk etsa kering semikonduktor

-

SF6 (sulfur hexafluoride): Digunakan untuk etsa kering semikonduktor dan sebagai gas penebat

-

NF3 (nitrogen trifluorida): Digunakan untuk etsa kering semikonduktor

Gas rumah hijau selain CO 2 (selepas ini GHG) dikira dengan mendarabkan pelepasan langsung dari kilang kami dengan potensi pemanasan global (GWP), yang merupakan pekali penukaran CO 2.

Pada tahun fiskal 2024, di Kilang Matsumoto dan Tsugaru, yang mengeluarkan semikonduktor, kami sedang berusaha untuk menyesuaikan pirolisis pada sistem gas ekzos semua saluran pengeluaran semikonduktor yang dipasang sebelum 2010*. Pirolisis ini mampu mengurai 90% atau lebih gas rumah hijau yang terkandung dalam gas ekzos.

Melalui usaha ini, kami telah mengurangkan kira-kira 9,000 tan gas rumah hijau selain CO₂ pada tahun 2024.

-

*

-

Barisan pengeluaran semikonduktor yang dipasang pada tahun 2010 dan kemudiannya dipasang dengan pirolisis sebagai standard.

Sumbangan produk kepada pengurangan CO₂ Masyarakat

Di Fuji Electric, kami berhasrat untuk menyumbang kepada pengurangan CO 2 seluruh masyarakat melalui inovasi dalam teknologi tenaga elektrik dan tenaga haba kami; Untuk tujuan ini, kami menggalakkan pelanggan kami menggunakan tenaga bersih dan peralatan penjimatan tenaga kami untuk membantu mengurangkan pelepasan CO 2 operasi. Untuk mengira kesan pengurangan CO 2 bagi produk operasi yang dihantar pada fiskal 2009 dan kemudian, kami menganggap produk tersebut beroperasi sepanjang tahun.

Kami mengira pengurangan dalam pelepasan CO 2 menggunakan persamaan berikut: (“Jumlah pelepasan produk sedia ada Fuji Electric” – “Jumlah pelepasan produk baharu Fuji Electric”) x “bilangan unit dalam operasi”

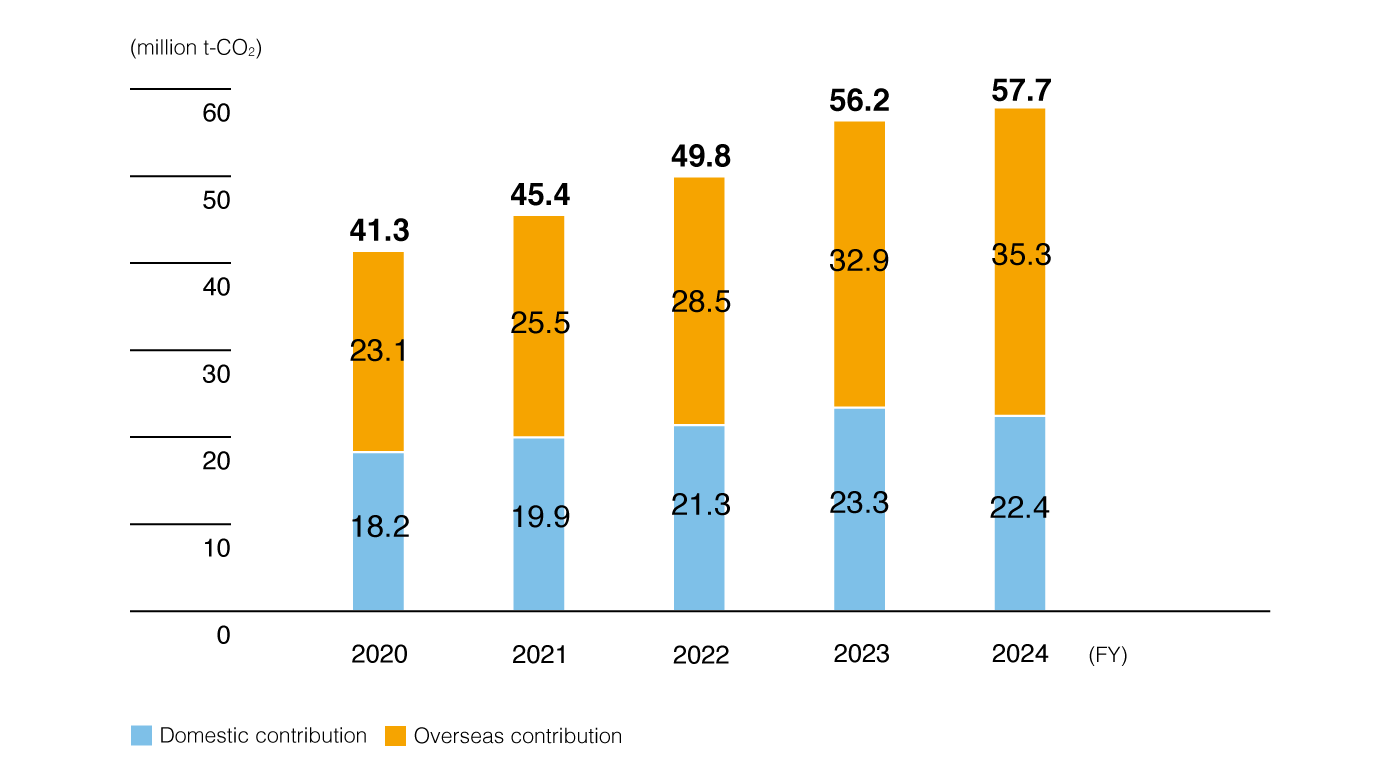

Sumbangan kepada Pengurangan CO₂ oleh Produk Kami yang Digunakan dalam Fiskal 2024: Sasaran dan Keputusan

Pada fiskal 2024, kami mencapai sasaran kami dengan kesan pengurangan sebanyak 58 juta tan berkat penggunaan peralatan penjimatan tenaga, seperti penyongsang dalam segmen Power Electronics, modul IGBT dalam segmen Semikonduktor dan tenaga bersih dalam segmen Tenaga. Peningkatan dalam kesan pengurangan ialah 1.4 juta tan untuk segmen Industri, dan 0.4 juta tan untuk segmen Tenaga, tahun ke tahun.

Produk Mesra Alam Fuji Electric

Boleh diperbaharui, seperti penjanaan kuasa geoterma dan hidroelektrik, adalah sumber tenaga bersih yang menyumbang kepada pencegahan pemanasan global. Ini kerana mereka menggunakan kuasa alam untuk menjana elektrik dan tidak mengeluarkan gas rumah hijau. Jika kita boleh menggunakan tenaga bersih untuk membekalkan elektrik kepada isi rumah yang dilayan oleh loji janakuasa penghasil CO 2 sedia ada, kita boleh memenuhi keperluan elektrik mereka tanpa mengeluarkan sebarang pelepasan CO 2. Dengan menggalakkan percambahan tenaga bersih, Fuji Electric menyumbang kepada pengurangan CO 2 dalam masyarakat.

Pada fiskal 2024, dalam segmen Tenaga, kami menyampaikan dua unit penjanaan kuasa geoterma dengan jumlah kapasiti 93 MW, dan enam unit hidroelektrik dengan jumlah kapasiti 56 MW. Kemudahan ini boleh menghasilkan kira-kira 1,300 juta kWj tenaga boleh diperbaharui setahun, menyumbang kepada pengurangan pelepasan CO₂ masyarakat bersamaan dengan kira-kira 580 ribu tan CO₂ setiap tahun, yang sebaliknya akan dipancarkan oleh sumber kuasa haba.

Produk yang dibekalkan oleh segmen Industri, seperti penyongsang, boleh dimasukkan ke dalam kilang dan peralatan lain untuk merealisasikan penjimatan tenaga dalam kawalan motor dan pelbagai bidang lain. Sementara itu, sistem kuasa tidak terganggu (UPS) yang dibekalkan oleh segmen Tenaga boleh menyumbang kepada penjimatan tenaga dengan meningkatkan kecekapan melalui kehilangan penggunaan elektrik yang lebih rendah. Semikonduktor kuasa, tawaran dalam segmen Semikonduktor, digunakan sebagai peranti utama dalam produk elektronik kuasa tersebut, menyumbang kepada kecekapan tenaga melalui penukaran tenaga dan kawalan kuasa yang sangat cekap.

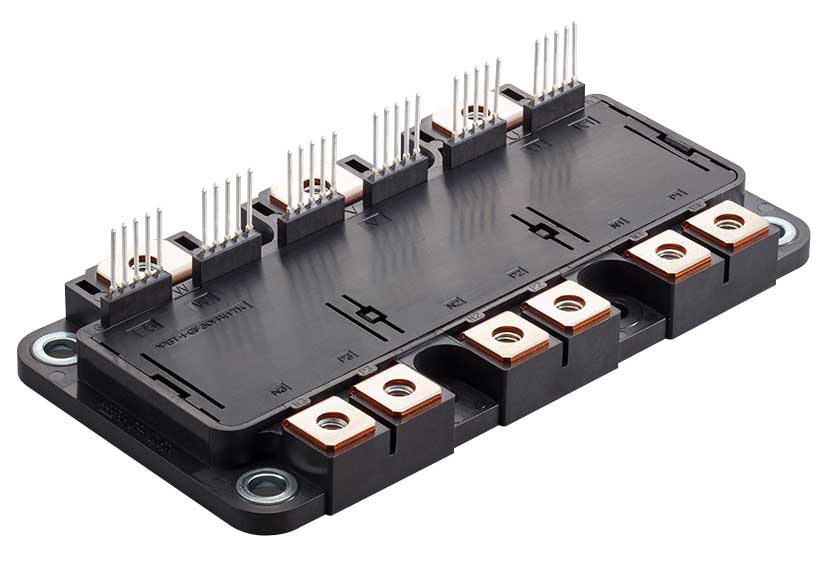

Dalam bidang semikonduktor kuasa industri dan automotif, Fuji Electric terus memajukan pembangunan peranti dan modul yang mencapai kehilangan rendah dan kecekapan tinggi. Khususnya, kami telah memberi tumpuan untuk mengembangkan barisan modul IGBT industri generasi ketujuh kami dan mengurangkan saiz modul automotif kami.

Pada fiskal 2024, dalam sektor perindustrian, kami melancarkan siri baharu modul IGBT industri berkapasiti besar yang dipanggil siri "HPnC", yang direka untuk sistem tenaga solar dan angin. Kami mengembangkan siri ini sehingga 2,300V untuk menyokong sistem penukaran kuasa yang lebih besar, menyumbang kepada kecekapan penjanaan yang lebih baik. Dalam bidang automotif, kami membangunkan modul RC-IGBT padat yang menggabungkan teknologi RC-IGBT dan pembungkusan terkini kami. Produk ini mencapai lebih kurang 57% pengecutan dalam volum berbanding model konvensional (berdasarkan kuasa keluaran undian), menyokong elektrifikasi kenderaan ringan dan kecil.

Terima kasih kepada inisiatif ini dan lain-lain dalam sektor perindustrian dan automotif, pada fiskal 2024 produk semikonduktor kuasa kami membantu mengurangkan pelepasan CO 2 sebanyak 5.8 juta tan. Melangkah ke hadapan, kami berhasrat untuk meningkatkan jualan produk semikonduktor kerugian rendah kami dan menyumbang kepada pengurangan yang lebih besar dalam pelepasan CO 2.

Mengurangkan Pelepasan Gas Rumah Hijau Merentasi Rantaian Bekalan

Fuji Electric mengumumkan komitmennya untuk membantu merealisasikan masyarakat dengan pelepasan karbon bersih-sifar. Melangkah ke hadapan, sebagai tambahan kepada aktiviti pengeluaran, termasuk perolehan dan pengangkutan, kami akan menyasarkan untuk mencapai neutraliti karbon di seluruh rantaian bekalan dengan berusaha untuk mengurangkan CO 2 yang dikeluarkan apabila produk sedang digunakan.

Skop3 pelepasan

Gas rumah hijau (Skop 3) yang dikeluarkan secara tidak langsung dari hulu ke hilir dalam keseluruhan rantaian bekalan Fuji Electric telah dikira sejak fiskal 2012 berdasarkan garis panduan*1 yang dikeluarkan oleh Kementerian Alam Sekitar.

Pada fiskal 2022, kami memperoleh pensijilan SBT. SBTi telah menganggarkan pelepasan dalam kategori yang tidak dapat kami kira dan telah mengesahkan bahawa tidak perlu menambahkannya pada skop sasaran kami.

Pelepasan CO 2 daripada produk yang dijual (Skop 3, Kategori 11) menyumbang lebih daripada 90% gas rumah hijau yang dikeluarkan merentasi keseluruhan rantaian bekalan kami.

Untuk mengira pelepasan Kategori 11 kami, dalam fiskal 2019 kami menentukan kedua-dua skop dan kaedah pengiraan untuk pelepasan daripada produk yang dijual.

Sejak itu, setiap tahun kami telah mengira pelepasan daripada penggunaan produk yang dijual dalam tujuh kumpulan produk terbesar kami, yang bersama-sama menyumbang kira-kira 80% daripada pelepasan semua produk kami.

Skop untuk Pelepasan Gas Rumah Hijau

-

Skop 1: Pelepasan langsung daripada sumber yang dimiliki atau dikawal oleh syarikat (pembakaran bahan api dan proses perindustrian)

-

Skop 2: Pelepasan tidak langsung daripada penggunaan tenaga yang dibeli (termasuk haba dan wap)

-

Skop 3: Semua pelepasan tidak langsung yang tidak termasuk dalam Skop 1 dan 2 (pelepasan daripada syarikat lain dalam rantaian nilai, dsb.)

Pendekatan untuk mengira pelepasan Skop 3 Kategori 11 (pelepasan CO 2 daripada produk yang dijual)

-

Produk akhir – produk yang digunakan pelanggan dalam keadaan sedia ada mereka

▶Produk dilindungi: relau elektrik industri, peralatan pengedaran dalam kedai dan peralatan penjanaan kuasa haba

▶Kaedah pengiraan: "no. unit dihantar" x "jumlah penggunaan kuasa tahunan (penggunaan bahan api)" x "jangka hayat dalam tahun" x "pekali kuasa" -

Produk perantaraan – produk yang pelanggan masukkan ke dalam produk mereka sendiri, sebelum dihantar kepada pengguna akhir

▶Produk dilindungi: semikonduktor kuasa, penyongsang voltan rendah, motor dan transformer

▶Kaedah pengiraan: "no. unit dihantar" x "jumlah kehilangan kuasa tahunan (kehilangan tenaga)" x "jangka hayat dalam tahun" x "pekali kuasa"

-

*1

-

“Garis Panduan Am mengenai Perakaunan Pelepasan GHG Rantaian Bekalan, Versi 3.0,” Kementerian Alam Sekitar

Skop 1: Pengeluaran gas rumah hijau langsung oleh syarikat pelapor itu sendiri.(cth. pembakaran bahan api, proses perindustrian)

Skop 2: Pelepasan tidak langsung daripada penggunaan elektrik, haba atau wap yang dibekalkan oleh orang lain.

Skop 3: Pelepasan tidak langsung selain daripada Skop 1 dan Skop 2(Emisi oleh pihak lain yang berkaitan dengan aktiviti syarikat)

-

Note:

-

Pengesahan oleh pihak ketiga telah selesai untuk keputusan tahun fiskal 2022

(unit:kt-CO 2)

Inisiatif Penjimatan Tenaga dalam Logistik

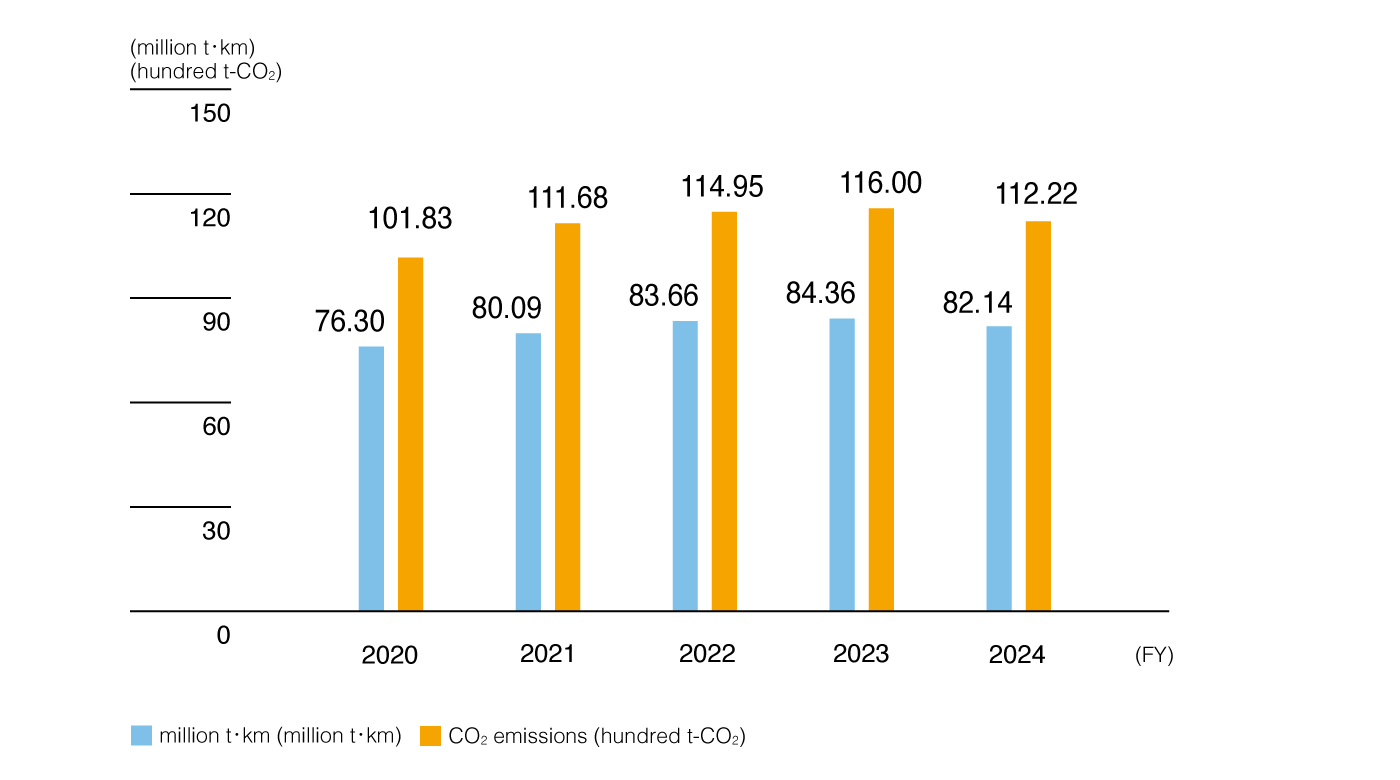

Dalam usaha untuk mengurangkan pelepasan CO 2 dalam bidang logistik, sejak 2006 kerajaan telah mewajibkan pemilik pengangkutan yang melebihi volum pengagihan tahunan sebanyak 30 juta tan kilometer untuk mengambil kira dan merasionalkan penggunaan tenaga mereka. Di Fuji Electric, kami merumuskan Garis Panduan Kewajipan Pemilik Kargo, dan mengira tenaga yang digunakan oleh setiap kilang kami.

Inisiatif untuk Mengurangkan Beban Alam Sekitar dalam Logistik

Beban logistik Fuji Electric pada fiskal 2024 menurun 2.6% tahun ke tahun, dengan pelepasan CO 2 menurun 3.3% tahun ke tahun juga; ini menunjukkan bahawa pelepasan CO 2 bagi setiap beban logistik kami bertambah baik dari tahun ke tahun.

Kami terus berusaha untuk menyelaraskan operasi logistik kami. Dalam perniagaan mesin layan diri kami, yang merupakan perniagaan berintensifkan beban logistik kami, kami sedang berusaha untuk mengembangkan inisiatif kaedah penghantaran kelompok* kami, dan ini telah membantu kami meningkatkan pelepasan CO 2 setiap beban logistik kami.

-

*

-

Kaedah penghantaran kelompok merujuk kepada kaedah pengedaran di mana produk mula-mula dihantar ke pusat penghantaran serantau dengan kenderaan 10 tan, kemudian diangkut secara individu ke setiap destinasi penghantaran dengan kenderaan 4 tan. Berbanding dengan kaedah penghantaran individu yang hanya menggunakan kenderaan 4 tan, kaedah ini melibatkan perbatuan yang lebih pendek dan dengan itu mengurangkan kesan alam sekitar.