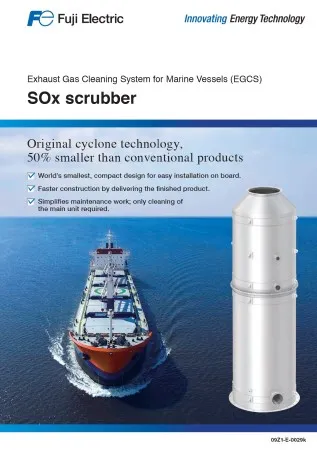

SOx Scrubber

FE World of Marine Technologies

FE World of Marine Technologies

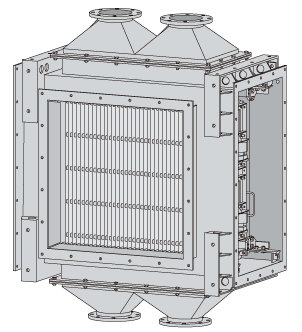

Electrostatic technology

Based on our electrostatic technology for tunnel ventilation systems, we are currently developing an electrostatic precipitator for ships.

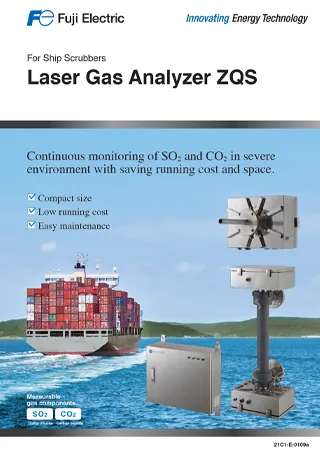

Measurement and analytical technology

The technology behind our laser gas analyser for ships is a product of our experience in developing air pollution monitoring and measurement equipment for industrial plants.

Control technology

At Fuji Electric, we offer a range of total solutions for factory automation systems: solutions that achieve energy savings and support efficient manufacturing processes.

Heat recovery technology

The technology and experience we have accumulated through our efforts in geothermal power generation plants serve as guides for the development of our heat recovery technology and energy-saving systems for ships.

Water treatment technology

Scrubber technology

Our SOx scrubber for ships utilizes cleaning technologies and is the result of our extensive experience in fuel cell development and geothermal power generation.

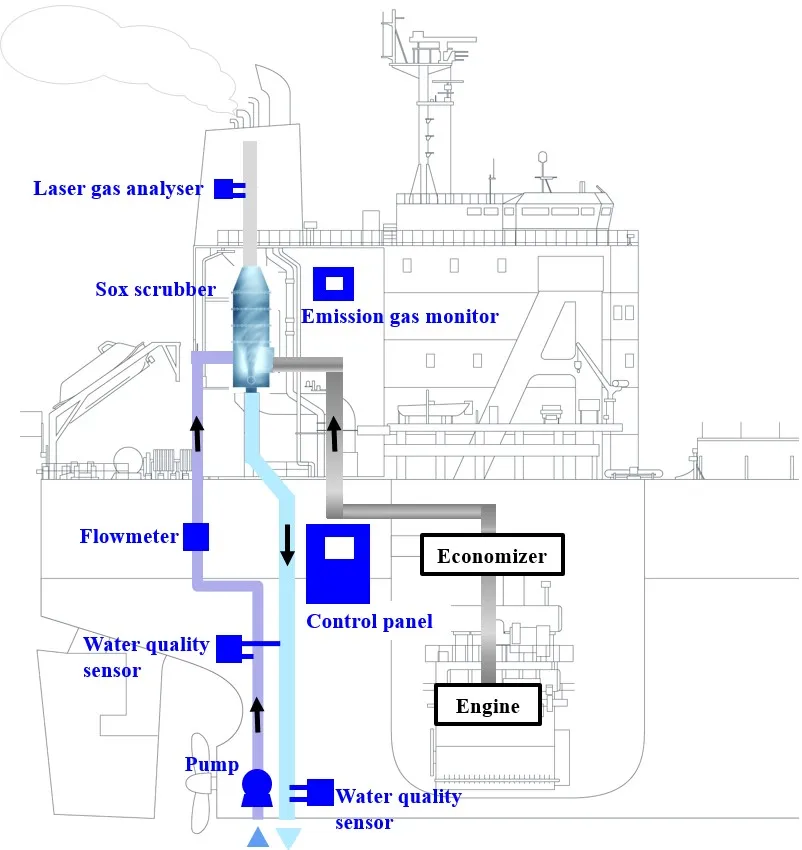

Fuji Electric’s EGCS

In such ways as scrubber technology, electrostatic technology, measurement and analytical technology, water treatment technology, heat recovery technology, and control technology, we at Fuji Electric have enhanced our core areas of expertise. These are all the results of decades of experience with our research and development efforts with land-based technologies. Now, we are re-applying our core technologies and expertise from the land to the sea. Through optimal integration of proprietary technology and other products and technologies, Fuji Electric has created a new value-added solution for ships.

Ship-to-shore two-way power supply system

Frequency conversion unit

Effective use of surplus power

-

Facilitates power supply from both land to ship and ship to land (when testing generator load)

-

Photo: System installed at Nagasaki Shipyard, Mitsubishi Heavy Industries

Energy-saving equipment

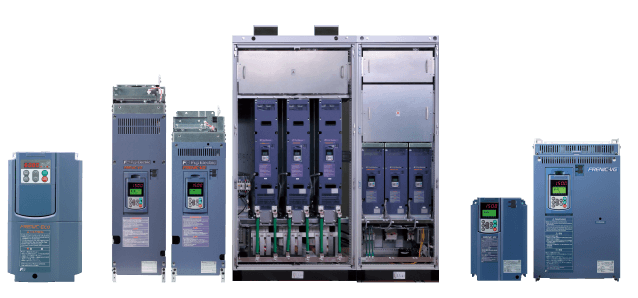

Drives and inverters

Electrification contributes to energy and labour savings, improving environmental performance

FRENIC-Eco Series

On-board fan, feed pump, cargo pump

FRENIC-VG Series (Unit type, Stack type)

Deck crane, deck equipment (e.g. windlass, mooring equipment)

Electric propulsion, side thruste

From land to sea, your one-stop provider of energy solutions for a cleaner planet

For more than 90 years, Fuji Electric has been innovating electric and thermal energy technologies, which form the core of society’s electricity use. We cover a broad range of business segments: from power electronics systems, power and new energy, and electronic devices to food and beverage distribution. Our aim is to bridge the gap between energy concerns and environmental health.

As a result of decades of working to optimize energy use and minimize environmental impact on land, Fuji Electric has managed to meet stringent land-based standards. To meet a new frontier of environmental regulation, we are now extending our goal to the oceans.

Taking our years of experience from land to sea, we seek to provide customers with an environment-friendly, energy-saving solution for ships. This notion is conveyed in the SaveBlue concept.

Catalogue downloads

Creative use of space and resources is a hallmark of ship design, and it is the guiding philosophy behind Fuji Electric’s SOx scrubber and laser gas analyser.

Fuji Electric’s solution, SaveBlue, is an exhaust gas cleaning system (EGCS) that allows continued use of heavy fuel oil (HFO): With a compact size that facilitates ease of installation, it is suitable for both retrofitting and new builds.

Contact

-

TEL

-

+81-(0)-3-5435-7168

-

Reception hours

-

Mon.- Fri. 9:00 - 17:00 (JST)

Related information

Notice

-

April 18,2025EGCS:Regarding Routine Maintenance of the Laser Gas Analyzer (ZQS)

-

April 17,2025EGCS:Regarding the software update for Chelsea's Water Quality Meter (Sea Sentry)(Caution)

-

July 31,2023Bubbles or Films Generated Near the SOx Scrubber Outlet while Berthing (FESN-2119Follow-up Report)

-

January 31,2023Replacement of parts during Intermediate Survey

-

September 30,2022Undisplayed PAH Value