Cooling Systems

Transformer Cooling

The optimum cooling type to be used is selected taking into consideration the amount of heat to be removed, special conditions at the installation site and other requirements of the customer. The following cooled types are commonly used:

(1)Forced Oil Circulation

(a) OFWF (forced oil, forced water) cooled type

-

Shell and single tube type oil to water cooler with oil pump, or

-

Shell and double tube type oil to water cooler with oil pump

(b) OFAF (forced oil, forced air) cooled type

(c) Forced oil self cooled type: Panel radiator with oil pump

(2)Natural Oil Circulation

(a) OFWF (forced oil, forced water) cooled type

(b) OFAF (forced oil, forced air) cooled type

Among the above cooling systems, OFWF and OFAF are widely used. In the case of a large rectifier transformer with multiple windings, the forced oil cooled system is essential. Cooling oil passage ducts are provided in the core and winding through which cooling oil circulates to remove the heat.

OFWF is most effective for a compact and space-saving transformer.

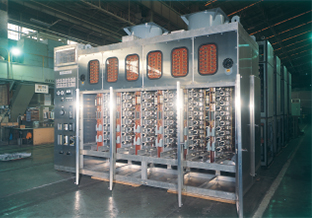

Rectifier Cooling

Various cooling systems are available, as shown below, for the rectifier assembly. Fuji Electric will suggest the cooling system best suited to the customer's particular needs.

(1) Water Cooled

(a) WFWF (forced water, forced water) cooled type

(b) WFAF (forced water, forced air) cooled type

(2) Air Cooled

(a) AF (forced air) cooled type

(b) AFWF (forced air, forced water) cooled type

(c) AFAF (forced air, forced air) cooled type

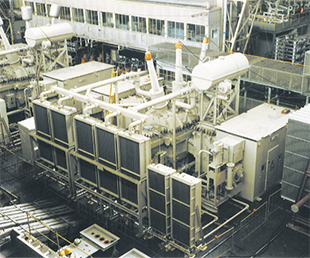

Water Cooled Rectifiers

Water is the most effective cooling media in practice. In the case of Fuji Electric's water cooled rectifiers, de-ionized water is used for the primary cooling media, which is circulated through the heat sinks to remove the heat generated by the diodes or thyristors.

The de-ionized water warmed up after circulating in the heat sinks is then cooled by a WFWF (forced water, forced water) or WFAF (forced water, forced air) heat exchanger.

In order to maintain sufficiently high-resistivity of the de-ionized water, some portion of the circulating de-ionized water is continuously bypassed through a cartridge type ion-exchanger provided in the cooling system.

Its resistivity is maintained at over 106 ?-cm and continuously monitored by a conductivity meter in the system. De-ionized water tubes are connected between heat sinks.

The tubes are made of a cross-linked polyethylene material which is particularly durable, both mechanically and thermally.

The de-ionized water circuit is carefully designed so as to avoid electrolytic corrosion in the system and to keep the water te

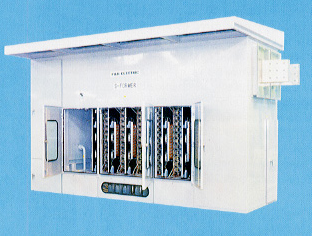

Air Cooled Rectifiers

The AF cooled open type is the simplest of all forced air cooled rectifiers. This rectifier type is designed for indoor installation where filtered and well-convected cooling air is available.

AFAF is suitable for rectifiers for outdoor installation where industrial cooling water is not available.