Data Gathering

Data acquisition software: ACQ![]()

Data acquisition software: PISAC![]()

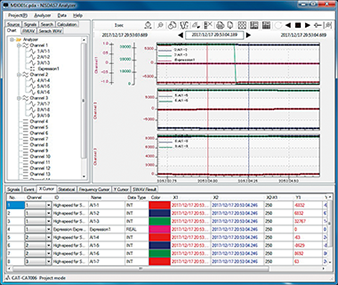

High-speed data acquisition

f(s)NISDAS can collect PLC data as quickly as 1 ms.

The acquired data is immediately saved to hard disk and displayed in real time in the chart window.

Recording of large-volume of continuous data

Since f(s)NISDAS saves data to the hard disk of a personal computer, continuous data can be stored over a long period of time as long as sufficient disk capacity is available. For example, if 70 GB of hard disk space is available, for continuous 243-word *1 storage of data sampled every 50 ms, data for 4 months or even longer can be stored *2.

-

*1

-

One word is assumed to be 16 bit data.

-

*2

-

Since this is an example, this is not a guaranteed period.

Output the acquisition state to an external device

The collection status can be notified to an external device. You can check the collection error at a remote location. The external device can be either a MICREX-SX/ViewXX or a network-controlled signaling light. MICREX-SX/ViewXX must implement a dedicated programme. Please contact us for details.

Collecting data from multiple PLC in various ways

You can collect high-speed and large-capacity data from PLC of several MICREX series connected to Ethernet. Modifications or sets to PLC are not required and can be collected later.You can use Ethernet, USB, loader port, etc.Expert(View-C), Imports variable-name information from standard loader. Depending on the placement of the variables to be collected, the data can be collected in any manner from the address and variable name.Various collections can be made according to the status of test adjustments, operations, failure investigations, etc.

PISAC data acquisition from the plant control programmable logic controller (PLC) (option)

The internal memory of the plant control PLC that is connected to MICREX-SX by the processor link (P-LINK, PE-LINK, FL-NET) can be acquired and monitored via the broadcast area. Dedicated programs are required respectively for MICREX-SX and the plant control PLC (PIII, IX).

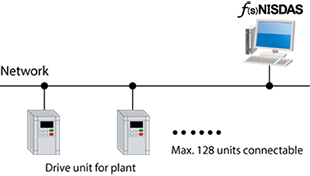

Data acquisition of drive unit for plant (option)

Connecting f(s)NISDAS to the drive unit for plant *3allows to acquire and monitor data in the drive unit*4.

-

Main functions and performances Trace-back data acquisition(1 ms sampling, etc.*5)

-

*3

-

Drive unit for plant: For details, refer to the “Data acquisition-INV acquisition (DDC)” column in the specification table (back cover).

-

*4

-

In order that this function can be realized, plusFSITE option (IT solution device that allows to connect a network of field device having serial terminal) must be installed on the drive unit.

-

*5

-

The sampling time depends on a plusFSITE.

FL-net (OPCN-2) broadcast data acquisition

Acquires FL-net (OPCN-2) broadcast area 1 and area 2 together. Separately available FL-net communication Board (NP3L-FL3PXS) is required for acquisition. Compatible with both standard and expert notation.