Environmental Management Organizational Framework

We at Fuji Electric are united in tackling environmental issues based on our policy of contributing to society by developing our energy-related business globally.

Environmental Management Organizational Framework

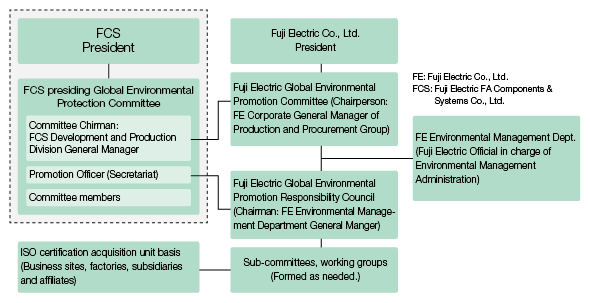

To promote environmental management, Fuji Electric established the Global Environmental Protection Committee, which is headed by the director responsible for the environment and which reports directly to the president, and deliberates and decides on basic and comprehensive policies.

Moreover, when necessary we also hold sessions of the Fuji Electric Global Environmental Promotion Responsibility Council, which is comprised of the officers responsible for environmental management at Fuji Electric's principal factories and affiliated companies, and which looks into the development of major policies, as well as examines solutions for new issues.

Environmental Management in accordance with ISO 14001

Fuji Electric has put in place environmental management systems at all of its production and sales bases in Japan as well as all of its overseas production bases and is working to acquire third-party certification.

In addition, all employees take part in environmental education programs, and everyday environmental activities, such as those targeting reductions in energy and water use as well as waste production, have become an entrenched part of our corporate culture.

The Status of ISO 14001 Certification

(As of March 31, 2018)

| No. of Sites with EMS | Japan | Overseas | |

|---|---|---|---|

| Total | 29 | 13 | |

| Acquired | 29 | 13 | |

| Not yet acquired | 0 | 0 | |

Status of Sites Not Yet Acquired

Overseas: Fuji Electric (Zhuhai) Co., Ltd., acquired certification in fiscal 2017

Internal Environmental Audits

Environmental site inspection in Fuji Electric Motor (Dalian)

Since fiscal 2003, the internal divisions responsible for environmental management administration have continued to conduct annual environmental site inspections, which double as internal audits, of ISO 14001-certified sites.

The frequency of inspections is based on the degree of environmental impact of each site. In fiscal 2017, on-site inspections were conducted at 14 domestic sites and three overseas sites. During inspections, fact sheets* were used to track information related to environment risks. Collaboration is pursued with individual sites to reduce environment impacts and improve risk management with the aim of limiting exposure to the identified risks.

In addition, since fiscal 2016, we have been conducting inspections via Internet-based video calls at sites that are not inspected. As this method makes it possible to confirm actual conditions at sites and offer specific guidance, it has allowed for inspections that are more effective than the previously employed check sheet method.

*Fact sheets combine an environment risk map, for recording the location of environmental facilities at each site and relevant historical data, and an environmental performance sheet, which is used to record environmental performance at each site, including energy consumption, chemical substance discharge and waste volume.

Environmental Violations in Japan

| Fiscal year | Fines, Penalties | Recommendation by government | Primary exceeding reference value, notices |

|---|---|---|---|

| 2013 | 0 | 0 | 0 |

| 2014 | 0 | 0 | 0 |

| 2015 | 0 | 0 | 2 * |

| 2016 | 0 | 0 | 0 |

| 2017 | 0 | 0 | 0 |

| * | ・Waste Management and Public Cleansing Act: Requested transporter to handle products to be discarded outside transporter’s authorized area. (internal construction divisions) |

| ・Waste Management and Public Cleansing Act: Discovered after the fact that work had been commissioned to unlicensed transporter. (a consolidated subsidiary) |

Operational flow will be reviewed to ensure that orders cannot be placed without confirming approval status.

Overseas sites: No legal violations during fiscal 2017.

Status of environmental communication with local communities

| Fiscal year | Briefing / Social get-together / Presentation, etc. | Opinions / Requests / Complaints, etc. | |

|---|---|---|---|

| (of which, number remaining unaddressed) | |||

| 2013 | 13 | 6 | 0 |

| 2014 | 12 | 14 | 0 |

| 2015 | 18 | 5 | 0 |

| 2016 | 26 | 10 | 0 |

| 2017 | 30 | 10 | 0 |

Fiscal 2017 examples

Briefing / Social get-together / Presentation, etc.: Forums for exchanges of opinion with local residents and companies, factory tours, and regular volunteer activities

Opinions / Requests / Complaints, etc.: Response to requests for cleanup activities around factories, cooperation with work-experience programs for junior high school students, adjustment of direction of streetlights, etc.

Going forward, Fuji Electric will continue to engage in communication with stakeholders in local communities to contribute to environmental improvement.

Environmental Risk Management

In promoting environmental management, we must reinforce environmental risk management at each of our production sites in order to maintain stable production.

Management via fact sheets was started in fiscal 2014 for all domestic production sites, and this has made it possible to conduct risk management for both facilities and equipment and environmental performance. We will continue to refine the fact sheet and use it not only for risk management but in energy and resource conservation activities as well.

Measures for Responding to Climate Change Risks

| Risk factors | Manufacturing sites | Measure Details |

|---|---|---|

| Depletion of water resources | Shenzhen | We increased the water recycling ratio to 80% by introducing recycling facilities. |

| Matsumoto, Zhuhai | We are purifying a portion of factory wastewater for everyday use and recycling water to meet the pure water requirements of manufacturing processes. [Related Rink : Initiatives at Matsumoto Factory] | |

| Increases in water prices | Malaysia | As this sites uses the most water, we are stepping up water-saving measures to achieve our 30% usage volume reduction goal by 2020. |

| Floods | Thailand | When establishing a new factory to reinforce production systems, we chose location at high elevation to mitigate flood-related disaster risks |

| Blackouts resulted from torrential rain | Matsumoto, Yamanashi | We implemented response measures through a monitoring system using early weather change alerts and took steps to ensure stable electricity supplies through UPSs and in-house generation facilities for crucial equipment. |

| Transportation congestion or disruption resulted from torrential rain | Mie | We have established a system allowing production to be shifted to different days when large-scale disruptions to transportation, distribution, or production are forecasted prior to torrential rain. |

Illustration of Environmental Risks

Fuji Electric establishes specific environment risk maps for each factory in order to guide environmental preservation activities and help reduce the impact on the environment should an accident occur. These maps provide diagrams that illustrate a clear picture of information regarding the facilities, equipment, and work processes with the potential to impact the environment as well as information related to the factory premise and buildings. Accordingly, these maps make it easier to share and communicate environmental risk information.

Environment risk maps have been established for all 21 domestic factories. We revise and update these maps each year to ensure the information they provide is up-to-date.

In fiscal 2017, we constructed environment risk maps for factories in China, Thailand, Malaysia, and the Philippines.

In preparing these maps, we conducted investigations on matters such as the chemical substance and oil usage and storage logs of these factories, and the findings of these investigations were combined with information on factory premises and buildings to create diagrams.

Note: Details of environment risk maps Information contained includes histories of soil contamination surveys and purification measures; chemical substance storage and usage logs; details on environment-related facilities; diagrams of water intake and exhaust systems, steam supply systems, and power systems; building earthquake resistance levels; and buildings using asbestos.

Prevention of Emission of Pollutants into Water and Air

In order to prevent environmental pollution, Fuji Electric has installed treatment equipment at bases that utilize chemical substances and manages the quality of water used in these bases to ensure that chemical levels do not exceed established environmental standards. We also conduct periodic emergency response drills to guarantee that we are prepared should an abnormality be detected.

Furthermore, in order to ensure compliance with environmental standards, we have equipped in-house generation equipment (excluding emergency-use backup generators) with emission treatment equipment to limit the release of NOx into the atmosphere.

We also strive to limit the release of SOx into the atmosphere by using low-sulfur fuels.

Soil Purification

We were able to develop a complete understanding of the circumstances regarding soil and underground water pollution at all domestic production bases by fiscal 2007.

We then undertook the purification of soil at all 13 bases at which pollution levels exceeded standards, and these purification measures have since been completed at nine bases.

We then conducted soil investigations at the timings described in the Soil Contamination Countermeasures Act of Japan*1. It was determined that certain bases required monitoring of underground water through these surveys, and we have continued to perform monitoring at these bases accordingly.

As of March 2018, we were in the process of conducting purification measures at three bases*2 and underground monitoring at two bases*3.

Overseas, many countries are in the process of instituting laws and regulations equivalent to Japan’s Soil Contamination Countermeasures Act, and we have thus begun to conduct land-use history assessments and compile electronic maps as dictated by such laws and regulations.

Furthermore, we perform soil investigations prior to purchasing or selling land, whether in Japan or overseas, thereby confirming the inherent pollution risks.

- *1. Timing for soil investigations: When abolishing specific facilities designated by the Water Pollution Control Act or when conducting land alterations of a defined level

- *2. Mie, Matsumoto, and Azumino (Fuji Meter)

- *3. Kawasaki and Fukiage