Environmental Management

We at Fuji Electric are united in tackling environmental issues based on our policy of contributing to society by developing our energy and environment business globally.

Message from the Executive Officer Responsible for Environmental Management Administration

Our new structure provides a base for moving forward with environmental management, and we are earning society’s trust as the leader in the energy and environment sector.

Michio Abe

Executive Officer Responsible for

Environmental Management Administration

General Manager, Production Headquarters

Fuji Electric Co., Ltd.

Our management policy declares that Fuji Electric will develop our energy and environment business globally and contribute to society. The launch of the New Fuji Electric in April 2011 is driving us to redouble our efforts to reduce our own environmental impact, as well as society’s overall impact through the use of our products.

We have carried out energy waste reduction measures for the past four years to reduce our own environmental impact, cutting our energy costs by about 10%. As we attempt to reduce the environmental impact of our products within society, we are also working to make the power consumed by individual products and services, as well as the effects of reduced CO2 emissions, “visible” to the consumer. This is our way of responding to society’s demand for power conservation.

We formulated the Fuji Electric Environmental Vision 2020 in FY2009 to serve as a directive for our medium- to long-term environmental activities, focusing on three activities: Stop Global Warming, Create a Recycling-Oriented Society, and Meet Our Corporate Social Responsibilities. Our goal is to gain society’s trust as the leader in the energy and environment sector.

In line with government initiatives, Tohoku Electric Power and Tokyo Electric Power required their large-scale consumers of electricity to cut maximum electrical power use in the summer of 2011 by 15%. Fuji Electric cooperated with this plan by reducing power usage by 25% through measures such as shifting production to other regions in Japan and abroad and via thorough energy conservation activities.

Environmental Vision 2020

Fuji Electric’s core business is energy and environment, so reducing impact on the global environment is our priority social responsibility.

Accordingly, we formulated the Fuji Electric Environmental Vision 2020 in April 2009 to serve as a directive for our medium- to long-term environmental activities. In addition to reducing the environmental burden, we aim to be lead the energy and environment field by helping to lessen the environmental impact of society as a whole through our products.

Environmental Policy

Fuji Electric’s basic polices on environmental protection were established in 1992, declaring within and outside the Group its efforts to address diverse global environmental problems. We also began working to reduce the environmental impact of our business activities.

We revise our policies when necessary in light of societal changes, and broadly amended them in June 2011 to emphasize our energy and environment business and global efforts.

Fuji Electric Basic Policies on Environmental Protection

(Established in 1992, revised in 2003)

The Fuji Electric Group is keenly aware of our social responsibilities as a good corporate citizen and we regard efforts to protect the global environment as one of our most important management tasks. We will strive to achieve a sustainable, recycling-based society in compliance with the following basic policies.

- Offering products and technologies that contribute to global environmental protection

We will provide the market with energy-saving equipment, new energy equipment, environment monitoring equipment, environmentally friendly equipment, and related technologies to contribute actively to the protection of the global environment. - Reduction of environmental burden through the product life cycle

We will strive to minimize the burden on the global environment throughout the product life cycle, from the procurement of materials to their disposal, when offering the Group's products to the market. - Reduction of environmental burden in business activities

We will promote environmental conservation in a number of ways, including energy conservation, reduction of waste, and reduction of harmful chemicals. We thus aim to reduce the environmental burden of business activities at every stage, from procurement of materials and parts to production and distribution. - Compliance with environmental laws, regulations, and standards

We will observe environmental regulations of not only the countries and regions where Group companies operate, but also those where our products are used. In addition, we will establish our own standards, where necessary, as a part of our efforts in environmental protection. - Establishment and continuous improvement of environmental management systems

We will promote environmental conservation by establishing Fuji Electric Group's own system to enhance environmental protection, set environmental targets, and achieve other environmental objectives. In addition, we will strive for continuous improvement through internal audits, etc. - Raising employees' awareness of environmental issues and contributing to society

We will strive to raise employees' awareness of environmental protection problems through our daily activities; all employees will be encouraged to contribute actively to society through environmental conservation activities, etc. - Promotion of communication on our environmental activities

We will disclose the Group's efforts in environmental protection, while promoting communication with society and reflecting its views in our efforts to continuously improve our environmental conservation activities.

Environmental Management Framework

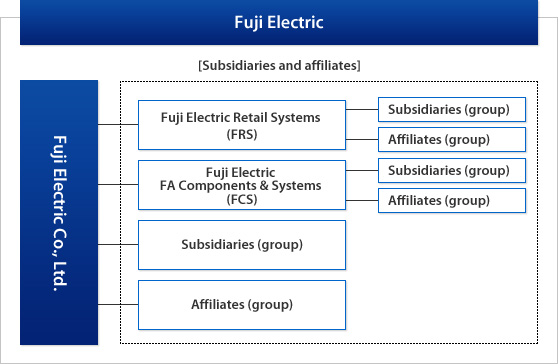

Environmental Management Organizational Framework

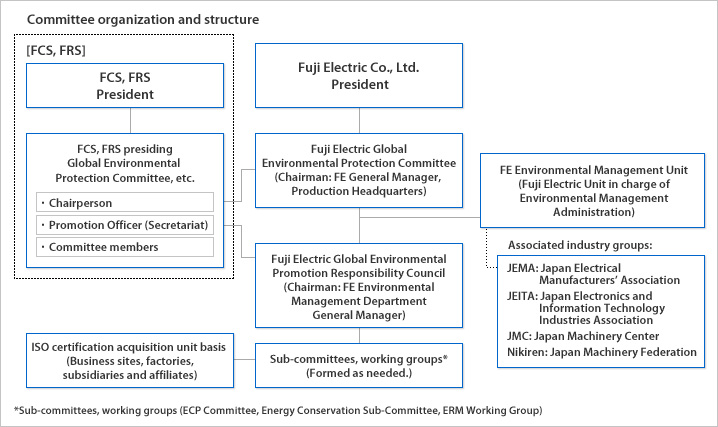

Fuji Electric considers environmental endeavors to be part of its CSR activities. We take a global approach in promoting environmental management.

Fuji Electric established the Global Environmental Protection Committee in July 2008. Led by the president, this committee is charged with deliberating and determining the basic, comprehensive environmental management measures for the company. We also hold sessions of the Fuji Electric Global Environmental Promotion Responsibility Council when necessary to look into the development of major policies and solutions on new issues. We also work to be the focal point for information exchange among the operating companies. Sub-committees and working groups are formed according to topic.

Fuji Electric Environmental Management Promotion Structure

Launch of Green Factory/Green Office Systems

Fuji Electric is engaged in developing the energy and environment business. To do so, we plan to strengthen our environmental management system (EMS) by introducing a Green Factory System and Green Office System in FY2011.

In the Green System, the plants and offices of each company are evaluated during the environmental patrols for degree of achievement of environmental conservation efforts at three stages, and Green Factory or Green Office certification is granted based on the degree of achievement.

In FY2010, we introduced this system on a trial basis at the units that had acquired ISO 14001 certification. Full-scale implementation will begin in October 2011.

Green Factory/Green Office Evaluation Factors

Evaluation factors- Environmentally friendly products and services

- CO2 reduction

- Reduced waste and efficient use of resources

- Chemical substance management and reduction of toxic atmospheric emissions

- Reduction of environmental risk and compliance

- Communication with local communities

Environmental Management in Accordance with ISO 14001 Certification

Fuji Electric has created environmental management systems throughout its production operations and at all its sales bases and is pursuing third-party certification. By FY2007, all domestic sites had gained ISO 14001 certification, and we currently practice environmental management that incorporates environmental initiatives into business operations.

Certification is also underway at overseas bases. As of the end of FY2010, only Fuji Electric Shanghai had not yet acquired certification. This company plans to relocate during FY2011 and aims to acquire certification after relocating.

ISO 14001 Certification Status (As of end March 2011)

| Consolidated businesses and operational sites | Japan | Overseas | |

|---|---|---|---|

| Number of sites | 32 | 10 | |

| Acquired | 32 | 9 | |

| Not acquired | 0 | 1 | |

Environmental Internal Audits

Environmental inspection at Fuji Electric Power Semiconductor Hokuriku factory

Since FY2003, the Group has conducted annual environmental site inspections of ISO 14001-certified sites. In FY2007, we began establishing an environmental compliance checklist for relevant laws and regulations and evaluating environmental risk to boost the effectiveness of our environmental management.

For FY2010, we had planned inspections for 27 sites in Japan and six overseas, but due to the Great East Japan Earthquake this was impossible at some locations. Consequently, site inspections were held at 25 sites in Japan and four overseas.

We revised the site inspection checklists in FY2010 in consideration of amendments to the Waste Law*1 and the Energy Conservation Law* of Japan We explained the details of the amendments and the strengthened regulations, as well as our responses.

We strove to enhance communications by explaining the status of Environmental Vision 2020 and overseas regulatory trends at annual environmental site inspections , as well as gathering opinions and suggestions from management-level employees. The opinions and suggestions provided to us will be reflected in future improvements.

*1 Waste Law

Full name, “Waste Disposal & Public Cleaning Law.” Due to amendment of this law in May 2010, fines levied against polluters have been stiffened, and provisions have been added to promote upgrading of waste disposal contractors.

*2 Energy Conservation Law

Full name, “Law Regarding the Rationalization of Energy Use.” Revision of the law in April 2010 changed the basic unit of application of the law from individual business sites to the company overall, and tightened other regulations.

Environmental Accounting

Fuji Electric introduced environmental accounting in FY2000 as a key means of assessing environmental management performance.

Using the 2005 guidelines released by Japan’s Ministry of the Environment, we established in-house calculation methods for environmental preservation costs and benefits. Each year, we ascertain and analyze these costs and benefits and disclose this information to the public. To expand our number of eco-products, we also calculate and total the “estimated benefits” of products when used by customers.

FY2010 Results

Environmental conservation costs totaled ¥14.0 billion, with investment at ¥1.81 billion and expenses at ¥12.21 billion. The environmental conservation benefit totaled ¥20.41 billion, including revenue from sales of valuable items at ¥1.19 billion, savings from energy conservation of ¥30 million, and estimated benefits of ¥19.19 billion.

Major environmental investment in FY2010 included installing SF6 and PFC gas separators at the Matsumoto factory (¥27 million) and updating air conditioning equipment at Ibaraki Fuji (¥17 million). We will continue to make planned investment and expand our sales of energy-saving products.

Policy on Environmental Accounting Calculations

We calculate “direct benefits,” such as revenue from sales of valuable items and energy conservation, as well as “estimated benefits,” which is a conversion to monetary value of the energy-savings benefit from the use by customers of existing environmentally friendly products (such as vending machines and some inverters) and energy-creating products (such as solar cells and geothermal systems).

Environmental Cost/Environmental Conservation Benefit (FY2010)

Period covered: April 1, 2010–March 31, 2011

Scope: 13 business sites + 16 consolidated subsidiaries (9 domestic companies, 7 overseas)

Environmental Cost (FY2010)

| Categories corresponding to business operations | Main Content | Total (Compared to previous term) |

Breakdown | ||

|---|---|---|---|---|---|

| Amount invested | Expenses | ||||

| 1 | Costs within the business area | 1,615 (+157) | 779 | 836 | |

| Pollution prevention costs | Cost of improving and maintaining of atmospheric and wastewater emissions treatment facilities and sound dampening equipment | 708 (+87) | 370 | 338 | |

| Global environmental conservation costs | Installation and maintenance of energy efficient equipment | 478 (+32) | 403 | 75 | |

| Materials recycling costs | Waste reduction, maintenance and management costs | 430 (+39) | 7 | 423 | |

| 2 | Upstream/downstream costs | Cost of processing discarded products | 40 (+18) | 19 | 21 |

| 3 | Management costs | Costs of environmental education for employees, environmental management systems operation, monitoring and measurement of environmental impact, environmental conservation measures | 606 (+87) | 14 | 592 |

| 4 | R&D costs | R&D costs for environmental conservation, such as energy conservation | 11,620 (+4,654) | 995 | 10,625 |

| 5 | Social activity costs | Greenery preservation, greening costs, and cost of support for environmental activities | 11(–97) | 1 | 10 |

| 6 | Environmental damage costs | Cost of excavation and processing of contaminated ground, charges for impact of pollution | 125 (+99) | 0 | 125 |

| Total | 14,017 (+4,918) | 1,808 | 12,209 | ||

Economic Benefit of Environmental Conservation Measures (FY2010)

| Categories corresponding to business operations | Main Content | Total (Compared to previous term) |

|---|---|---|

| Revenue | Amount received from sale of valuable items for recycling | 1,188 (+177) |

| Savings | Reduction of expense through energy conservation, reduction of landfill waste, reduction of water bill through water conservation | 31 (–222) |

| Estimated benefit | Energy reduction through use of environmentally-friendly products by customers | 19,187 (+11,107) |

| Total | 20,406 (+11,062) | |

Note 1: The “estimated benefit” is calculated as the economic benefit of energy savings when products with improved energy efficiency are used by customers, and is converted using the following formula:

Benefit (¥) = Σ〔(annual amount of electrical power consumed by former equipment - annual amount of electrical power consumed by new equipment)× Volume shipped annually in Japan × Electrical power standard cost〕(electrical power standard cost: ¥10/kWh)

Note 2: The “estimated benefit" includes environmentally friendly products such as solar cells, vending machines, cash counters, gas alarm equipment and LED lighting.

-

- Corporate Profile

- CSR

- Management Structure

- Social Report

- Environmental Report

- Topic 1/Reducing Environmental Impact through Our Products

- Topic 2/Reducing Environmental Impact at Our Production Bases

- Environmental Management

- Environmental Management Targets and Results

- Interplay between Business Activities and Environmental Impact

- Preventing Global Warming

- Recycling of Resources

- Management of Chemical Substances

- Preservation of Biodiversity

- Reducing Environmental Impact through Fuji Electric Products

- Together with Local Communities

- Research & Development