Preventive Maintenance of Substation

Comprehensive diagnostic services for substation power equipment

Stable operation achieved by proposed optimal conservation and improvement measures.

These services combine Fuji Electric's equipment diagnostic technologies and Schneider Electric's consulting methods to minimize risks to the stable operation of the substation power equipment and minimize any impact on the production equipment due to those risks.

Improved reliability and stability of substation power equipment

-

Understanding the reliability and stability of the customer's equipment makes it easy to examine the suitability of maintenance plans.

-

Management risks caused by equipment accidents are visualized.

-

Equipment maintenance plans are optimized.

Service features

-

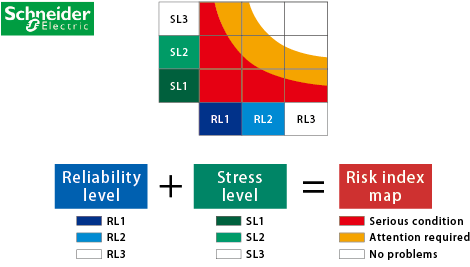

Equipment reliability and stress levels are visualized using risk index maps.

-

Degree of equipment deterioration can be understood using various diagnostic technologies.

MP4 consulting service

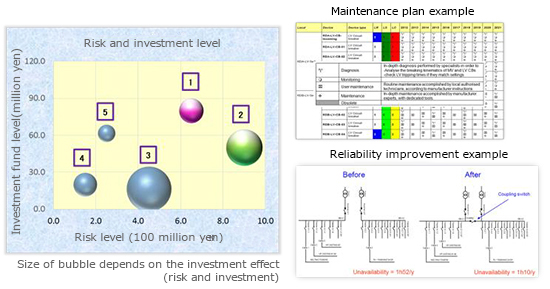

Stress and reliability levels are mixed, the risk index (importance) analyzed, and improvement plans proposed for stable operation of the equipment.

Substation power equipment diagnostic services

Equipment deterioration is diagnosed, remaining service life is assessed, and optimum maintenance plans are proposed.

【 Main services 】

-

Oil-filled transformer high precision remaining life assessment

-

Optical molded transformer deterioration diagnosis

-

Switch deterioration diagnosis

-

High voltage distribution panel partial discharge diagnosis

-

Substation equipment insulation deterioration diagnosis

-

Storage battery deterioration diagnosis

Main target equipment

Service overview

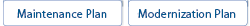

The MP4 Consulting Service consists of four steps.

MP4 Consulting Service

-

Extraction of parts critical to production

-

Critical time and cost to repair and recover after critical equipment shutdown

-

Assessment of safety, aging, protective coordination, power quality, and environment

-

Organization by stress level classification

-

Mixing of stress and reliability levels to determine importance and prioritize

-

Four improvement plan proposals based on results of examination up to Step 3

Content of improvement plan proposal

-

Measures to improve the capacity of facilities and improve quality

-

Maintenance and update plan road maps

-

Optimization of cost and investment plans

-

Visualization of risks

-

Improvement measures for accident prevention

Value provided by MP4

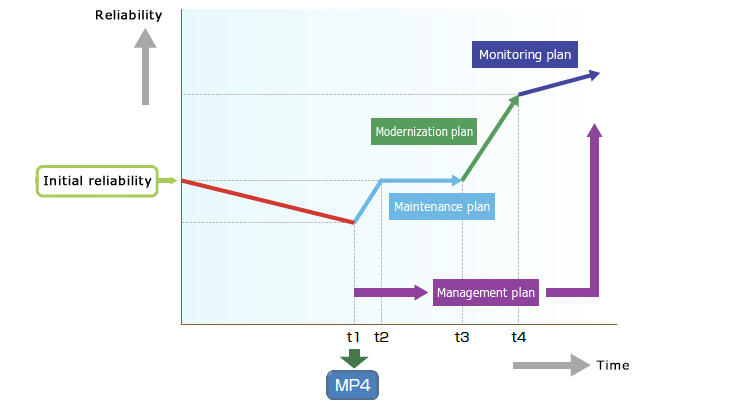

Examples of recommendations provided by MP4

Recommended measures for investment cost and amount of risk to be avoided are quantified.

When multiple facilities are involved, this makes it possible to set priorities.

Important notes about using these services

Since assessment and analysis are performed while equipment is in operation, shutdown is not required.

Equipment specifications and settings

Environmental conditions

-

Humidity, rust

-

Temperature

-

Dust, chemical corrosion

Operating conditions

-

Breaker lockout tag installation and procedures, implementation state

-

Power supply capacity, harmonics

-

Equipment deterioration: year of installation, number of operations and frequency, waste type, spare parts, etc.