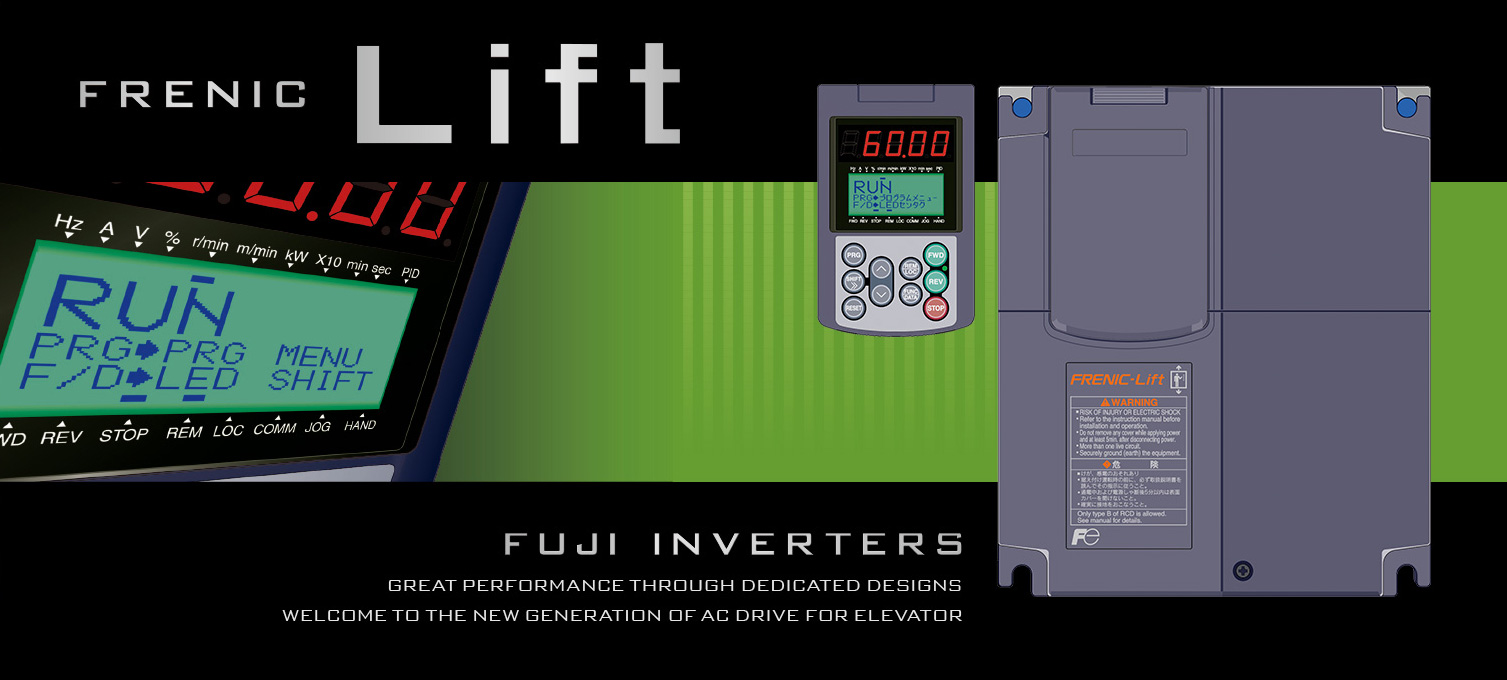

FRENIC-Lift

-

Lineup in Japan

-

FRENIC-VG

-

Product information

- Unit Type, Stack Type, Converters

- Comprehensive Line-up

- Improved Control Performance

- A Wide Range of Applications

- Easier Maintenance

- Easier Maintenance and Greater Reliability

- Adaptation to Environment and Safety

- How to expand the capacity range of the inverters (Stack Type)

- How to expand the capacity range of the PWM converters (Stack Type)

- Variation

- Applicable SiC Hybrid Module Model

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-MEGA (G2)

-

FRENIC-MEGA (G1)

-

Product information

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

- Prolonged service life and improved life judgment function

- Consideration for environment

- Global compatibility

- Function Safety

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

-

FRENIC-Ace (E3)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

- FRENIC-Ace (E2)

- FRENIC-Mini

-

FRENIC-HVAC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-Eco

-

Product information

- Product appearance

- Exploded view of main body

- Keypad switches and functions

- Monitor display & key operation

- New energy-saving

- Long life design of inverters

- Simplified maintenance

- Optimum functions for HVAC

- Environment and panel design

- Operator-friendly features

- Network compatibility

- Global compatibility

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

-

FRENIC-Lift(LM1S)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHR

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-VG

-

Lineup in Europe

-

FRENIC-VG

-

Product information

- Unit Type, Stack Type, Converters

- Comprehensive Line-up

- Improved Control Performance

- A Wide Range of Applications

- Easier Maintenance

- Easier Maintenance and Greater Reliability

- Adaptation to Environment and Safety

- How to expand the capacity range of the inverters (Stack Type)

- How to expand the capacity range of the PWM converters (Stack Type)

- Variation

- Applicable SiC Hybrid Module Model

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-MEGA (G2)

-

FRENIC-MEGA (G1)

-

Product information

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

- Prolonged service life and improved life judgment function

- Consideration for environment

- Global compatibility

- Function Safety

- Variation

- Specifications

- External Dimensions

-

Catalog Download

-

Product information

-

FRENIC-Ace (E3)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

- FRENIC-Ace (E2)

- FRENIC-Mini

- FVR-Micro

-

FRENIC-HVAC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-Eco

-

Product information

- Product appearance

- Exploded view of main body

- Keypad switches and functions

- Monitor display & key operation

- New energy-saving

- Long life design of inverters

- Simplified maintenance

- Optimum functions for HVAC

- Environment and panel design

- Operator-friendly features

- Network compatibility

- Global compatibility

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-AQUA

-

FRENIC-Lift(LM1S)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-Lift(LM2A)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHR

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-VG

-

Lineup in North America

-

FRENIC-VG

-

Product information

- Unit Type, Stack Type, Converters

- Comprehensive Line-up

- Improved Control Performance

- A Wide Range of Applications

- Easier Maintenance

- Easier Maintenance and Greater Reliability

- Adaptation to Environment and Safety

- How to expand the capacity range of the inverters (Stack Type)

- How to expand the capacity range of the PWM converters (Stack Type)

- Variation

- Applicable SiC Hybrid Module Model

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-MEGA (G2)

-

FRENIC-MEGA (G1)

-

Product information

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

- Prolonged service life and improved life judgment function

- Consideration for environment

- Global compatibility

- Function Safety

- Variation

- Specifications

- External Dimensions

-

Catalog Download

-

Product information

-

FRENIC-Ace (E3)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

- FRENIC-Ace (E2)

- FRENIC-Mini

-

FRENIC-HVAC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-Eco

-

Product information

- Product appearance

- Exploded view of main body

- Keypad switches and functions

- Monitor display & key operation

- New energy-saving

- Long life design of inverters

- Simplified maintenance

- Optimum functions for HVAC

- Environment and panel design

- Operator-friendly features

- Network compatibility

- Global compatibility

- Variation

- Specifications

- External Dimensions

-

Catalog Download

-

Product information

-

FRENIC-eRHR

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-VG

-

Lineup in China

-

FRENIC-VG

-

Product information

- Unit Type, Stack Type, Converters

- Comprehensive Line-up

- Improved Control Performance

- A Wide Range of Applications

- Easier Maintenance

- Easier Maintenance and Greater Reliability

- Adaptation to Environment and Safety

- How to expand the capacity range of the inverters (Stack Type)

- How to expand the capacity range of the PWM converters (Stack Type)

- Variation

- Applicable SiC Hybrid Module Model

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-MEGA (G2)

-

FRENIC-MEGA (G1)

-

Product information

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

- Prolonged service life and improved life judgment function

- Consideration for environment

- Global compatibility

- Function Safety

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

-

FRENIC-Ace (E3)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

- FRENIC-Ace (E2)

- FRENIC-Mini

- FVR-Micro

-

FRENIC VP

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

-

For Europe

- For China

-

- Document Download

- FRENIC-Lift(LM1S)

- FRENIC-eRHR

-

FRENIC-eRHC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-VG

-

Lineup in Asia

-

FRENIC-VG

-

Product information

- Unit Type, Stack Type, Converters

- Comprehensive Line-up

- Improved Control Performance

- A Wide Range of Applications

- Easier Maintenance

- Easier Maintenance and Greater Reliability

- Adaptation to Environment and Safety

- How to expand the capacity range of the inverters (Stack Type)

- How to expand the capacity range of the PWM converters (Stack Type)

- Variation

- Applicable SiC Hybrid Module Model

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-MEGA (G2)

-

FRENIC-MEGA (G1)

-

Product information

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

- Prolonged service life and improved life judgment function

- Consideration for environment

- Global compatibility

- Function Safety

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

-

FRENIC-Ace (E3)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

- FRENIC-Ace (E2)

- FRENIC-Mini

- FVR-Micro

-

FRENIC-HVAC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-Eco

-

Product information

- Product appearance

- Exploded view of main body

- Keypad switches and functions

- Monitor display & key operation

- New energy-saving

- Long life design of inverters

- Simplified maintenance

- Optimum functions for HVAC

- Environment and panel design

- Operator-friendly features

- Network compatibility

- Global compatibility

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-AQUA

- FRENIC eHVAC

-

FRENIC-Lift(LM1S)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHR

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-VG

-

Lineup in Taiwan

-

FRENIC-VG

-

Product information

- Unit Type, Stack Type, Converters

- Comprehensive Line-up

- Improved Control Performance

- A Wide Range of Applications

- Easier Maintenance

- Easier Maintenance and Greater Reliability

- Adaptation to Environment and Safety

- How to expand the capacity range of the inverters (Stack Type)

- How to expand the capacity range of the PWM converters (Stack Type)

- Variation

- Applicable SiC Hybrid Module Model

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-MEGA (G2)

-

FRENIC-MEGA (G1)

-

Product information

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

- Prolonged service life and improved life judgment function

- Consideration for environment

- Global compatibility

- Function Safety

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

-

FRENIC-Ace (E3)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

- FRENIC-Ace (E2)

-

FRENIC-Eco

-

Product information

- Product appearance

- Exploded view of main body

- Keypad switches and functions

- Monitor display & key operation

- New energy-saving

- Long life design of inverters

- Simplified maintenance

- Optimum functions for HVAC

- Environment and panel design

- Operator-friendly features

- Network compatibility

- Global compatibility

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

-

FRENIC-Lift(LM1S)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHR

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-VG

-

Lineup in Korea

-

FRENIC-VG

-

Product information

- Unit Type, Stack Type, Converters

- Comprehensive Line-up

- Improved Control Performance

- A Wide Range of Applications

- Easier Maintenance

- Easier Maintenance and Greater Reliability

- Adaptation to Environment and Safety

- How to expand the capacity range of the inverters (Stack Type)

- How to expand the capacity range of the PWM converters (Stack Type)

- Variation

- Applicable SiC Hybrid Module Model

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

- FRENIC-MEGA (G2)

-

FRENIC-MEGA (G1)

-

Product information

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

- Prolonged service life and improved life judgment function

- Consideration for environment

- Global compatibility

- Function Safety

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

Product information

-

FRENIC-Ace (E3)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

- FRENIC-Ace (E2)

- FRENIC-Mini

- FRENIC-Eco

-

FRENIC-Lift(LM1S)

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHR

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-eRHC

- Product information

- Variation

- Specifications

- External Dimensions

-

Catalog Download

- Document Download

-

FRENIC-VG

The FRENIC-Lift Series of exclusive AC Drives for operation of elevators are specially designed to have a number of improved features over previous elevator AC Drives, such as vastly lower torque ripple.We have incorporated the functions that customers find most necessary in elevator controls to provide an AC Drive that delivers performance that fits your elevator system.

I will explain the main functions and features of the series

Introducing series expansion, capacity, type

Detailed specification for each format is described

Outline drawing for each format is described