Research & Development

R&D Projects

Simulation Technology

# Digital Innovation Laboratory # Fundamental and cutting-edge technologies # Energy Saving # Safety and Security

-

High-precision analysis contributing to the high performance and high functionality of products

-

Visualization of phenomena contributing to the optimization of product structures

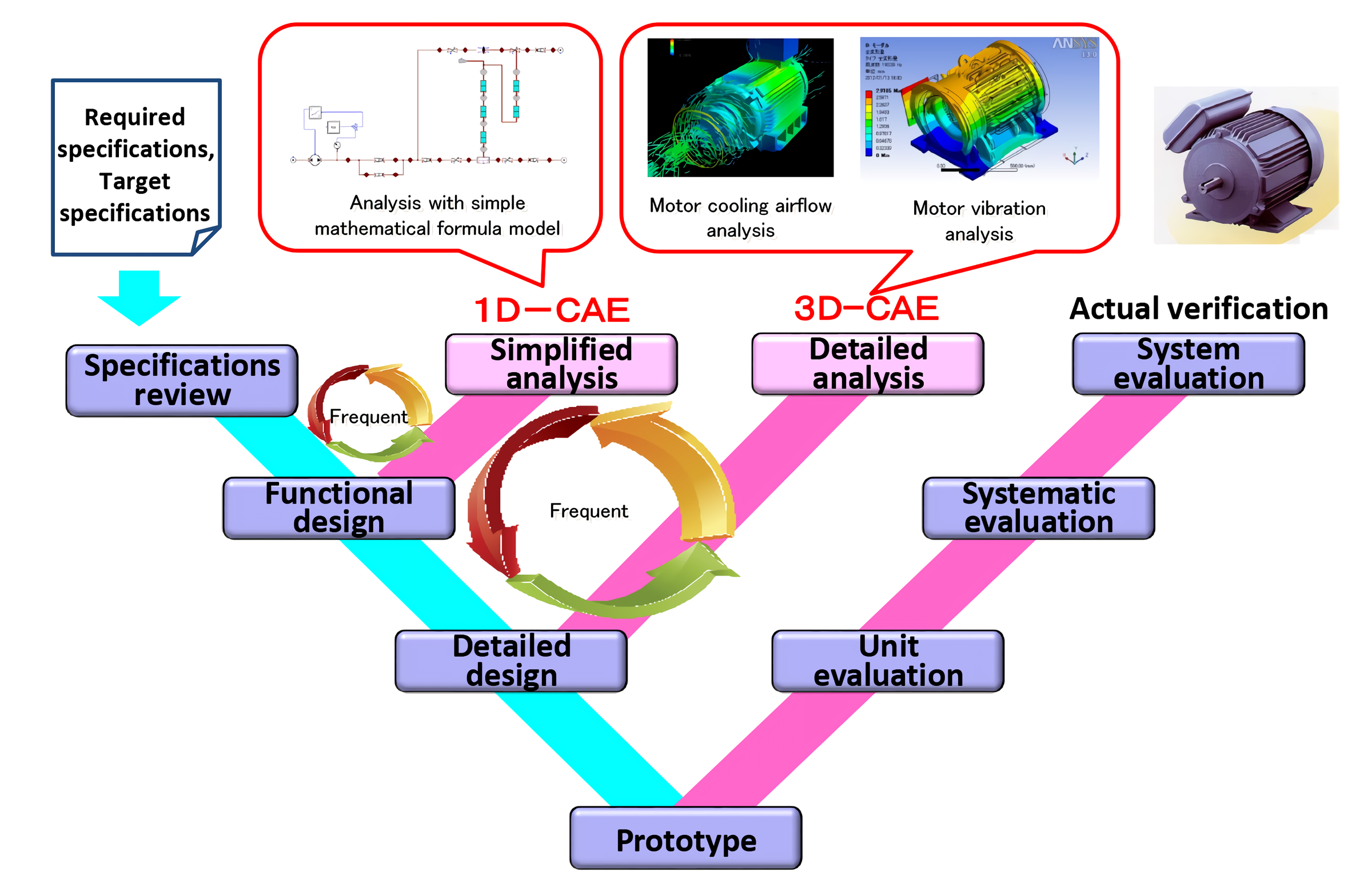

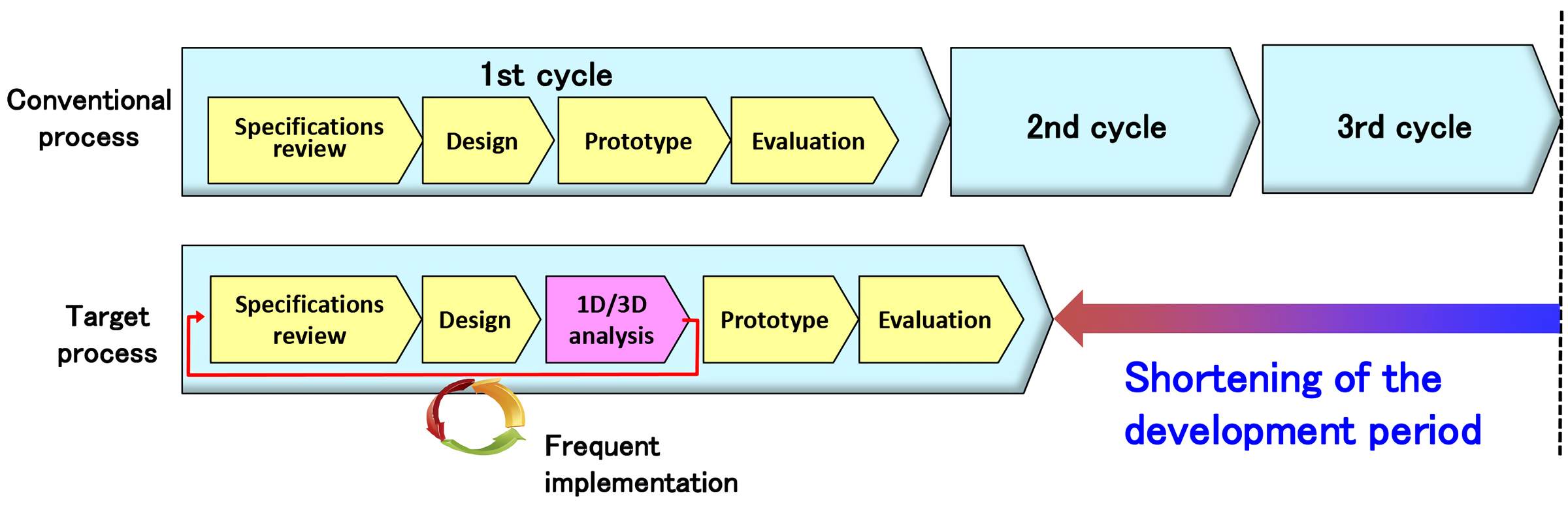

In order to realize high performance, high reliability, compact and lightweight products through the use of prediction and structure optimization at the development and design stage related to the mechanical strength, vibration resistance and temperature rise values of products, we have been developing and applying simulation technology in the areas of strength, thermal fluids and electromagnetic fields.

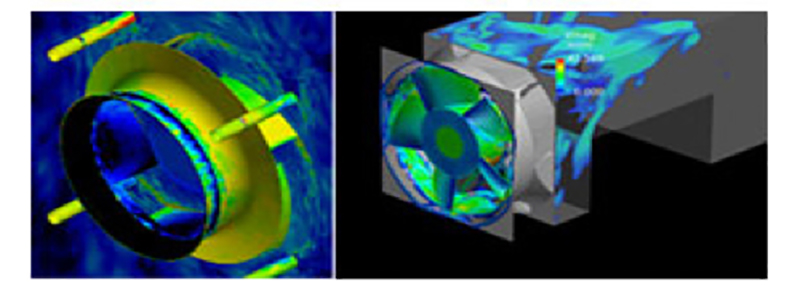

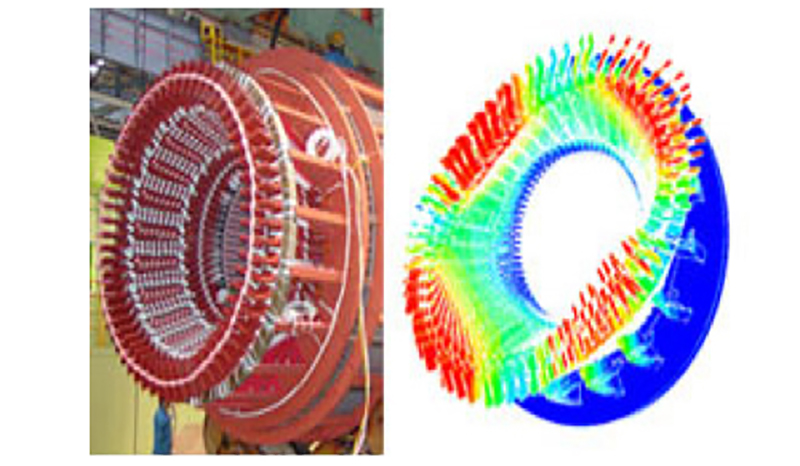

These simulations are used in an extensive number of products ranging from the estimation of stress levels and lifespan of the micro-regions of power semiconductor solder joints to the evaluation of the earthquake resistance, air flow and temperature in large-scale facilities such as power plants and data centers. Furthermore, this technology is utilized in physical mechanism elucidation and performance improvement for hard-to-measure targets, including behavior reproduction of arc gas flow inside distribution equipment, which can instantly raise temperatures anywhere between a few thousand to a few ten thousand degrees, as well as an understanding of flow phenomenon that accompany evaporation and condensation in geothermal power generation facilities.

(left figure: pressure fluctuation distribution; right figure: flow velocity distribution)

electromagnetic forces (deformation mode during resonance)