Research & Development

R&D Projects

Thermal Power Turbine Reliability Improvement Technology

# Advanced Technology Laboratory # Power Infrastructure # Fundamental and cutting-edge technologies # Energy Saving # Safety and Security

-

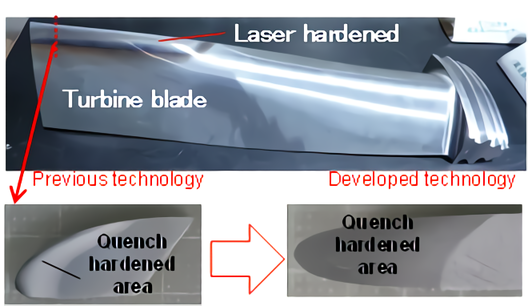

Longer service life through development of surface treatment technology

-

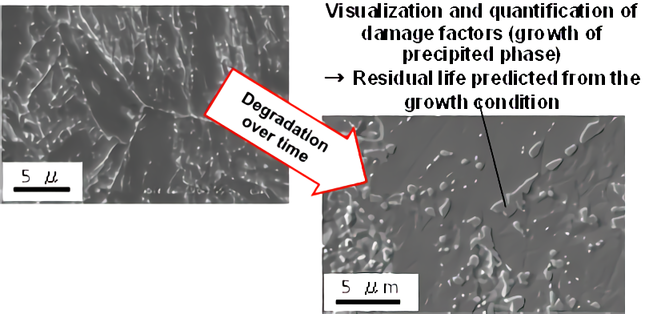

Prediction of residual life as product degrades over time

Thermal power plants generate power continuously using high-temperature, high-pressure steam over long periods of 20 years. The risk of damage increases with age, and so it is important to improve the reliability of turbines, which are the key components of power plants. A hardening treatment process has been developed to improve the wear resistance of the main component parts of turbines. Residual life assessment technology is being developed for predicting when turbine materials will break down due to degradation over time.