Preventing Global Warming

Fuji Electric recognizes the prevention of global warming as one of the most important topics related to its business strategy and works to reduce the energy used in its corporate activities.

Reducing Greenhouse Gases

CO2 Emission Reduction Targets and Results

Photovoltaic power generation systems (Tokyo factory)

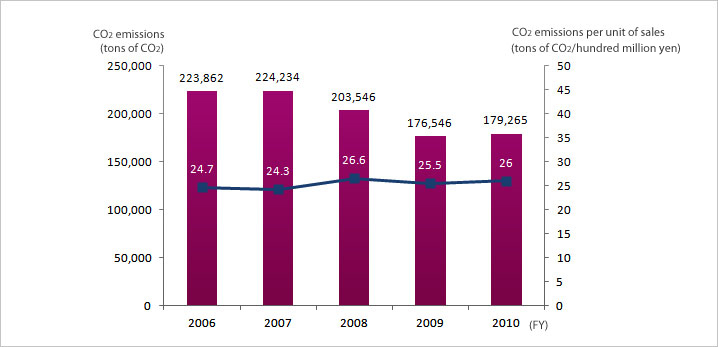

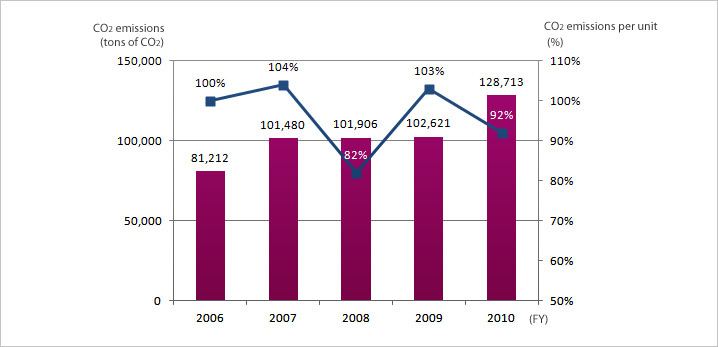

Fuji Electric participates in the voluntary action plan for the industry designed by four electronics industry organizations,*1 thereby helping to reach national emissions reduction targets. In addition to these production unit targets, since FY2007 we have set a voluntary target of reducing domestic energy-derived CO2 emissions by 6% by FY2010 relative to FY2006 levels, which we have driven through energy-saving activities. Moreover, in step with revisions to the Energy Conservation Law of Japan we are expanding the scope of CO2 emissions calculations from FY2010 from production activities only to include offices and all other operational sites. Historical data from FY2006 onward has been retroactively adjusted and is shown in the graphs below.

We achieved our goals for reducing CO2 emissions, cutting them to 179,265 tons in FY2010, down 19.9% from FY2006 as a result of continuing our energy conservation activities at all domestic production sites, including installing solar power generation equipment at two domestic facilities. We also succeeded in reducing overall energy cost (electric plus fuel cost) by approximately 11%.

Taking these results into consideration, we decided to take part in the government's trial emissions cap and trade scheme*2. We expect to exceed the 6% reduction target, and be recognized for achieving about 44,000 tons, constituting a surplus. We seek to achieve comparable energy conservation results overseas, so we are developing our overseas energy conservation efforts in parallel with those in Japan. To that end, we conducted energy conservation examinations at two overseas bases in FY2010.

In FY2011, we will establish our next voluntary action plan, taking into consideration "post-Kyoto" governmental and economic trends, and we plan to participate in overall electronics industry efforts. We are preparing the next voluntary action plan so that it corresponds to the long-term goals of Environmental Vision 2020.

*1 The Japan Electronics and Information Technology Industries Association, the Communications and Information Network Association of Japan, the Japan Business Machine and Information System Industries Association, and the Japan Electrical Manufacturers' Association

*2 This is the central feature of the Japanese Trial Emissions Scheme launched in October 2008. Participants voluntarily set emissions reduction targets and can supplement their own efforts to meet those targets by trading emissions allowances and credits.

Note:

1. This data covers the production bases and offices of all domestic consolidated subsidiaries, including Fuji Electric's offices.

2. Per unit sales figures are calculated as CO2 emissions over consolidated net sales.

3. Emission estimates use the emissions coefficient for electric power users (336 tons of CO2 per million kilowatt-hours in FY2010), taking into account the goal of a 20% emissions cut relative to 1990 levels by 2010, as specified by the Federation of Electric Power Companies of Japan.

Note:

1. Overseas energy and electric power conversion coefficients obtained from the Japan Electrical Manufacturers' Association website (Ver. 3, March 2006).

2. CO2 emissions per unit refers to units of sales, with FY2006 = 100.

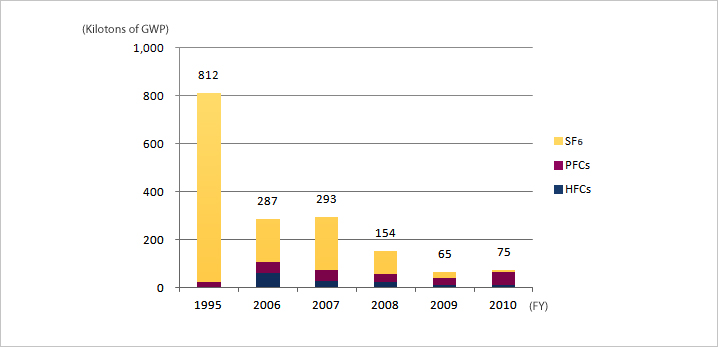

Reducing SF6 and Other Greenhouse Gases

Six types of gases, including CO2 and alternative chlorofluorocarbons, are considered greenhouse gases, as they contribute to global warming.

Of all the greenhouse gases, sulfur hexafluoride (SF6) is the most potent. Fuji Electric completed the transition from SF6 to alternative gases in the insulation testing processes at its semiconductor fabrication facilities in FY2009. Nonetheless, the semiconductor business was strong in FY2010, and as a result the use of perfluorocarbons (PFCs) used in semiconductor etching increased. Therefore, emissions of greenhouse gases other than CO2 were up 15% compared with FY2009.

In addition to activities targeting production processes, we are developing alternative technologies to eliminate greenhouse gases used in the product and otherwise helping to alleviate the environmental impact of products.

* Global warming potential (GWP) measures the relative greenhouse effect caused by a gas compared with CO2, which is assigned a GWP value of 1.

Energy Conservation Initiatives in Logistics

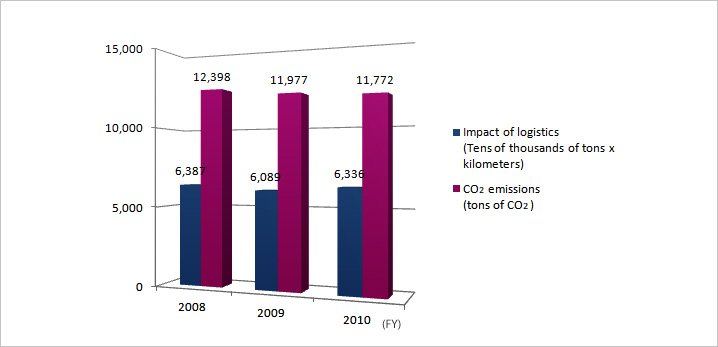

To reduce CO2 emissions in logistics, shippers are required to measure and improve their energy consumption.

Fuji Electric developed Guidelines on Shipper Obligations to facilitate a smooth and appropriate response by operating companies and sites to legislation that came into force in April 2006. It is also striving to enhance understanding of and to publicize the measurement range and computational procedures for CO2 emissions, methods of reporting, roles of key personnel and other factors. In order to ascertain the environmental impact of logistics activities, we have implemented the FeSMART* environmental management support system for centralized data management.

In addition, Fuji Retail Systems, which manufactures vending machines and other such products, has been designated a specified shipper by the Ministry of Economy, Trade and Industry, and is continuing to reinforce its energy-conservation activities.

* FeSMART (Fuji electric Sustainable MAnagement suppoRT system) enables registration of and access to all environmental data relating to the Group's factories and operating sites using a web browser on the Company's Intranet.

Boosting Environmental Awareness in Offices and Homes

Fuji Electric participates in the national "Challenge 25 Campaign" activities for the prevention of global warming, with our workplaces, including offices, promoting energy-saving activities.

In practice this means every company engages in energy conservation and waste reduction activities. Fuji IT Co., Ltd., was recognized for its efforts to develop organizational energy conservation activities and energy conservation tools in the 2010 TAMA Environmental Manufacturing Awards*, winning the Environmental Management Committee Prize.

Also, since FY2009 we have been encouraging employees to use the Ministry of the Environment's environmental house-keeping book to raise their awareness of energy conservation at home. As a result of incentives to stimulate participation in this program, such as provision of LED lighting to selected registered participants, the number of registered participants had risen to 752 by the end of FY2010. Fuji Electric's efforts in this program concluded when the Ministry of the Environment ended it on March 31, 2011.

*2010 TAMA Environmental Manufacturing Awards

These awards are sponsored by the Technology Advanced Metropolitan Area Association (TAMA) to recognize effective environmental technologies, products and responses toward issues such as CO2 emissions reduction.

-

- Corporate Profile

- CSR

- Management Structure

- Social Report

- Environmental Report

- Topic 1/Reducing Environmental Impact through Our Products

- Topic 2/Reducing Environmental Impact at Our Production Bases

- Environmental Management

- Environmental Management Targets and Results

- Interplay between Business Activities and Environmental Impact

- Preventing Global Warming

- Recycling of Resources

- Management of Chemical Substances

- Preservation of Biodiversity

- Reducing Environmental Impact through Fuji Electric Products

- Together with Local Communities

- Research & Development